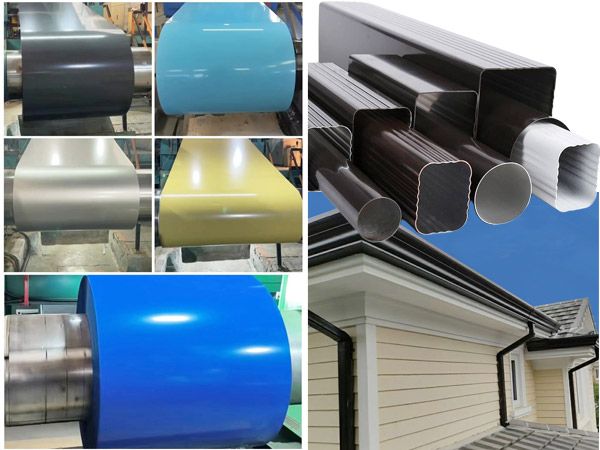

Prepainted aluminum coil for downpipes use 3105 H24 and 3003 H24 aluminum alloys as the base material, and are manufactured through roller coating with polyester (PE) or fluorocarbon (PVDF) coating processes. The prepainted aluminum coil possess characteristics such as corrosion resistance, ease of processing, and long-lasting color, making them ideal materials for modern building rain drainage systems.

Base aluminum material:

Color coated aluminum coils for downpipes typically use 3105 H24 or 3003 H24 aluminum alloys. These two alloys have moderate strength, good corrosion resistance, and processing performance, meeting the environmental requirements of downpipes exposed to the elements for extended periods outdoors. For example, 3003 aluminum alloy contains manganese, making its corrosion resistance superior to pure aluminum, while 3105 alloy further enhances its strength and formability through micro-alloying.

Thickness:

Typically between 0.024mm and 1.2mm, with prepainted aluminum coils used for downpipes generally around 0.9mm thick.

Width:

Ranges from 800mm to 1500mm.

Colors:

Mainstream colors include white, black, red, brown, and silver-gray. Custom colors can also be customized according to the RAL color chart.

Coating types:

Polyester Coating (PE): Lower cost, rich colors, suitable for regions with mild climates and weak UV radiation. Its film thickness is typically 25-28μm (front) and 15-18μm (back), meeting basic weather resistance requirements.

Fluorocarbon Coating (PVDF): Offers superior weather resistance, withstanding extreme environments from -50℃ to 150℃, and exhibits excellent color stability, suitable for high-altitude, coastal, or high-UV areas. For example, many stately-looking curtain wall buildings in the United States use fluorocarbon-coated aluminum coils.

Surface treatment:

The aluminum coil undergoes double-sided roll coating. The front coating protects the aluminum from rainwater corrosion, while the back coating prevents damage caused by friction with the wall during installation. Some products also add active chemical molecules to the coating to form a self-healing protective layer, extending service life.

Processing of aluminum gutter coil:

Roll coating process:

A continuous roll coating production line is used, employing steps such as degreasing, chemical pretreatment, coating, and baking to ensure uniform coating adhesion. A dust-free workshop environment avoids defects such as dust and particles, guaranteeing a smooth surface. BCM Aluminum Industry can achieve precise control over single-coat thickness of 15μm and double-coat thickness of 25μm, achieving zero color difference standards.

Forming process:

When color coated aluminum coils are processed into downpipes, they undergo bending, welding, and rail pressing. Their excellent mechanical properties (such as bending strength and ductility) allow aluminum coils to be easily formed into square, round, and other irregularly shaped pipes without deformation after cutting.

Customization Services:

Some companies support customization of color, thickness, and width according to customer requirements. For example, prepainted aluminum coils with thicknesses from 0.018mm to 1.5mm and widths from 800mm to 1600mm, and provides deep processing services such as slitting, embossing, and leveling to meet the design needs of downpipes in different architectural styles.

Advantages of prepainted aluminum coil for downpipes:

Lightweight design:

Aluminum's density is only 1/3 that of steel, significantly reducing the weight of downpipes and lowering the load-bearing pressure on buildings, while also facilitating installation and transportation.

Corrosion resistance and long lifespan:

The naturally formed oxide film on the surface of aluminum, combined with a protective coating, can resist corrosion from acid rain and salt spray, resulting in a service life of over 20 years. In contrast, galvanized iron downpipes are prone to rust, and plastic pipes may crack due to UV aging.

Environmental protection and recyclability:

The production process of color coated aluminum coils uses chromium-free treatment solutions, meeting environmental standards. After disposal, the aluminum material is 100% recyclable, reducing resource waste.

Combining aesthetics and functionality:

Prepainted aluminum coils can mimic natural textures such as wood grain and stone grain, or offer thousands of color options, upgrading downpipes from functional components to architectural decorative elements.

BCM produces prepainted aluminum coils for downpipes, made from 3000 series manganese-aluminum alloy substrate and a high-quality PE/PVDF coating, and crafted using advanced roller coating technology, these aluminum coils offer both superior practicality and aesthetics. The substrate itself has rust-resistant properties, and the dense, weather-resistant coating withstands acid rain, salt spray corrosion, and extreme temperature differences from -45℃ to 260℃. They are durable, colorfast, and rust-free, easy to bend and shape during processing, and the coating is resistant to peeling. Color options cover mainstream color schemes and support customization using the RAL color chart. Furthermore, they are environmentally friendly and recyclable, offering both high cost-effectiveness and long-lasting durability, making them the preferred material for building drainage systems.