High-performance polyester (HDPE) coated aluminum coil, has good heat resistance and cold resistance, good chemical stability, high rigidity and toughness and good mechanical strength.

HDPE coated aluminum coil is applicable to chemical industry, metallurgy, electric power, coastal areas, plateau and other areas with high requirements for UV resistance and corrosion resistance, as well as building interior and exterior panels with special requirements for anti pollution.

HDPE coating has the advantage of good aging resistance and corrosion resistance. And its acid resistance is very good, which is 5-6 times of that of ordinary PE coated aluminum coil. When polyester resin is changed into hydrophilic polyester with strong antifouling property, the coating surface has strong self-cleaning and pollution resistance properties. The weathering life is more than 15 years.

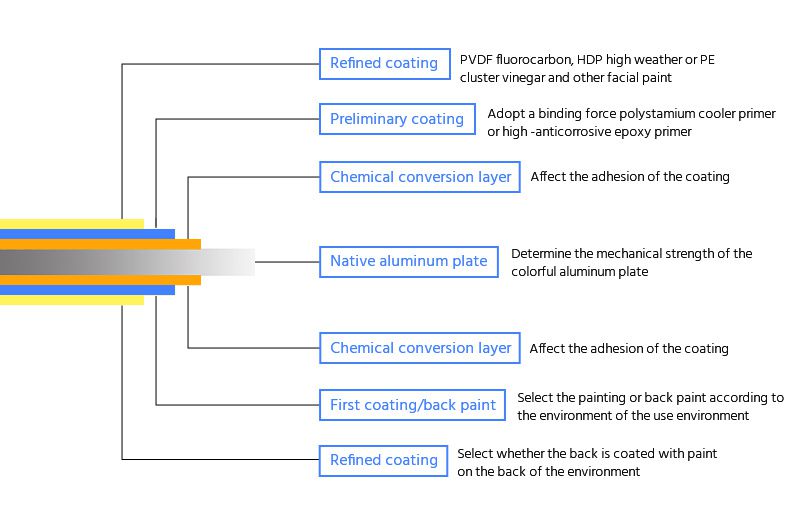

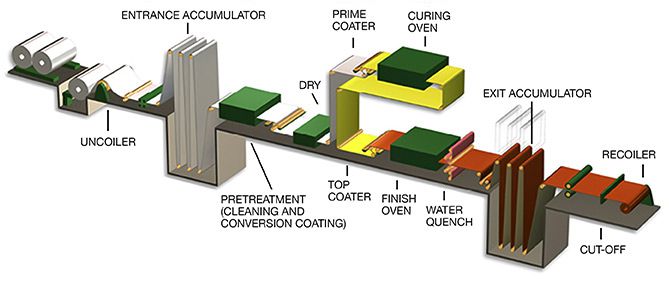

BCM Aluminum’s HDPE coated aluminum sheet substrate is made of high-quality aluminum coil and high-performance polyester coating with superior performance. It is equipped with high-tech, high-performance roller coating process, combined with international advanced production technology. Effectively control the accuracy of the sheet, flatness, uniform color, smooth and bright. The product has excellent processing performance, heat resistance and cold resistance, good chemical stability, high rigidity and toughness and good mechanical strength.

Alloy | AA1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5052, 6061, 8011, etc |

Coil thickness | 0.018-1.5mm |

Coil width | 30-2000mm, Standard 1240mm, MAX 2020mm |

Coil weight | 0.5 to 5.0 tons per coil |

Surface treatment | PE/PVDF coated, Embossed, Mill finish, Mirror Finish, Powder coated, Wood grain, Stone grain, Checkered |

color | white series, metallic series, dark series, gold series(accept color customs), RAL/PANTONE or as color chart or customized |

Packing | Standard exporting packing/ or at buyer's requirement |

Trade Terms | FOB/CIF etc |

Diameter | 405mm, 505mm, 508mm |

Coating thickness | 14-28 microns(PE:≥14micron, PVDF:≥25micron) |

Coils core diameter | 150mm,405mm,505mm |

Temper | O - H112 |

gloss | 20-100%(matte:≥20,glossy:≥60) |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

Test Item | National standard | Test Result |

Color Difference | ΔE≤2.0 | ΔE≤1.0 |

Gloss Difference | ≤10 | ≤5 |

Coating Thickness | Two layers Min 23μm | ≥25μm |

Three layers Min 30μm | ≥34μm | |

Pencil Hardness | ≥HB | HB |

T-bend | ≤2T | ≤2T |

Adhesion | Grade 0 | Grade 0 |

Impact | ≥50kg.cm | ≥50kg.cm |

Boiling water Resistance | 2h No change | 4h No change |

Solvent Resistance | 200 times paints remaining | 500 times no break |

Acidity Resistance | 5%HCL 24hrs No change | No change |

Alkali Resistance | 5%NaOH 24hrs No change color △E≤2.0 | No change |

Nitric acid Resistance | △E≤5.0 | △E≤5.0 |

Oil Resistance | 20#oil 24hrs No change | No change |

Salt Spray Resistance | 4000hrs ≤Grade 1 | No change |

Abrasion resistance | ≥5L/μm | ≥5L/μm |

Dirt Resistance | ≤5% | <5% |

Color retaining | 4000 hrs△E≤4.0 | 4000 hrs △E≤3.0 |

Gloss weaken Level | 4000 hrs ≤ Grade 2 | 4000 hrs ≤ Grade 2 |

Chalking | No change | No change |

Warranty:

Regular PE: 3-5 years;

High Performance PE(HDPE): 6-9 years;

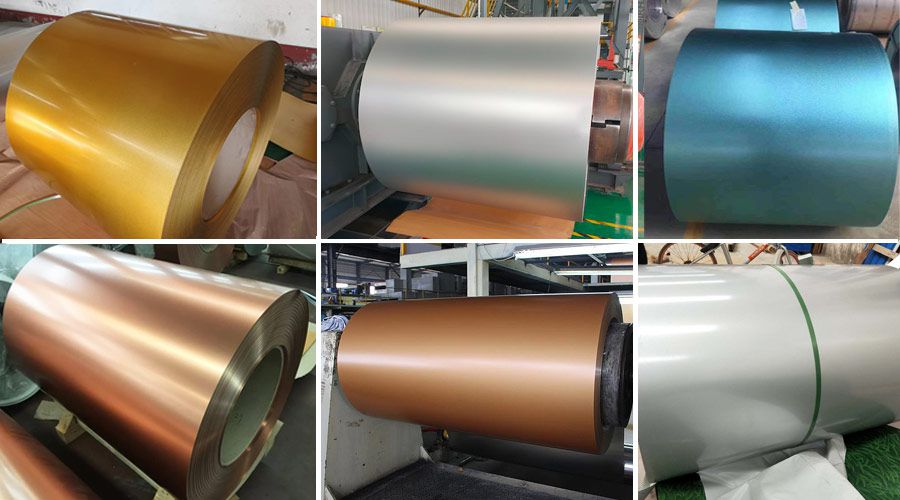

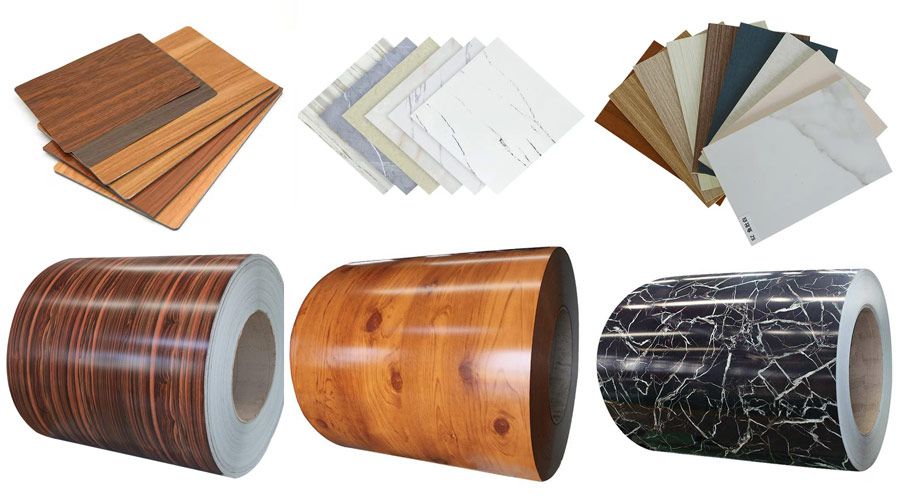

HDPE coated aluminum coils can be processed into a variety of different colors and textures such as metallic color, wood grain color, marble color, etc. by special surface treatment technology to meet different architectural styles and decoration requirements.

Standard Color

The standard color of HDPE coated aluminum coils is modulated according to the Ral color card. The basic colors are red, yellow, blue, green, white, gray and other colors and their derivative colors, which are suitable for most conventional applications.

Metallic Colors

The Metallic color of HDPE color coated aluminum coils simulate metal textures, such as silver gray, bronze, rose gold, etc., which add a sense of luxury and class to the product and are often used in high-end architectural decoration.

Printing Series

The printing series achieve natural texture effects such as wood grain and stone grain through special coating technology, providing more diversified choices for architectural design, esuitable for places that pursue natural and environmental protection concepts.

Excellent Weather Resistance:

High-performance polyester color coated aluminum coils typically utilize a high-durability polyester (HDP) coating, a high-molecular-weight polymer composed of a special polyacid and polyol. This coating is almost completely transparent to UV rays, enhancing gloss retention and chalking resistance. It is also resistant to photolysis and offers a guaranteed service life of over 15 years under normal conditions, significantly improving the 7-10-year lifespan of standard polyester (PE) coatings.

Excellent Mechanical Properties:

The coating offers increased hardness, stronger adhesion, and improved impact resistance. For example, color-coated aluminum coils with a HDP coating maintain excellent flexibility while better resisting impact and scratches. They also meet the requirements of complex processing techniques such as bending, cutting, and punching, and the coating resists peeling and cracking after processing.

Excellent Decorative Properties:

The HDP coating supports the mixing of any color from the RAL and Pantone color palettes, and its computerized color matching system ensures a color difference of ≤1.0, meeting the precise color requirements of various architectural and decorative projects. Some high-performance PE color coated aluminum coils also utilize advanced textured roller coating technology, such as 3D texturing, which creates a 0.5mm-deep, concave and convex texture on the aluminum coil surface. The texture feels like natural wood or stone, while the visual effect is clear and lifelike, creating a more outstanding decorative effect.

Environmental friendliness:

From the aluminum coil substrate to the surface coating, all processes are SGS-certified. VOC levels are far below national standards, meeting environmental requirements. No harmful substances are released during use, harmless to humans or the environment.

HDPE coated aluminum coil sheet is mainly used in homes, shopping malls, office buildings, hotels, schools, factories, banks, conference halls, stadiums, exhibitions, subways, airports etc indoor places.

Construction Industry

Exterior wall decoration: HDPE color coated aluminum coil can be used as building decorative panels, applied to exterior wall decoration, balcony decoration, etc.

Roof board: HDPE color coated aluminum coil can be used as roof board, which is lightweight and corrosion-resistant, suitable for various climate conditions, and also has fireproof and moisture-proof properties.

Automotive Industry

Body Panel: HDPE color coated aluminum coil is used for automotive exterior panels, such as doors, hoods, etc., which is lightweight and corrosion-resistant, can improve fuel efficiency and extend vehicle service life.

Roof and side decoration: used for roof and side decoration, providing a variety of color options to enhance the beauty of the car.

Logo and Advertising

Billboard: HDPE color coated aluminum coil is used to make outdoor billboards, with bright and long-lasting colors and not easy to fade. It can also be used to make road signs and other outdoor signs.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)