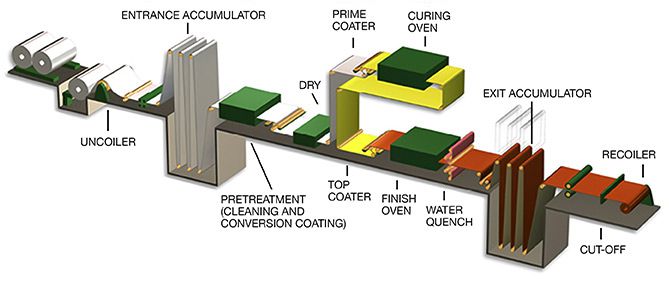

Polyester coated aluminum sheets are a type of aluminum material that has been coated with a layer of polyester paint. This coating process enhances the aluminum's durability, aesthetic appeal, and resistance to environmental factors. PE Coated Aluminum Coil come in a wide range of colors, textures, and finishes, which can be applied in many fields.

PE coating has good adhesion to the material, its price is lower than PVDF, and its color and luster selectivity is large, so it has a large amount of usage. In general outdoor environment, the basic corrosion resistance can reach 7-8 years. It is generally used in areas where air pollution is not serious or products that need to be processed for many times. Such as ordinary industrial plants, warehousing and logistics warehouses, traffic signs and other materials.

Alloy | AA1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5052, 6061, 8011, etc |

Coil thickness | 0.018-1.5mm |

Coil width | 30-2000mm, Standard 1240mm, MAX 2020mm |

Coil weight | 0.5 to 5.0 tons per coil |

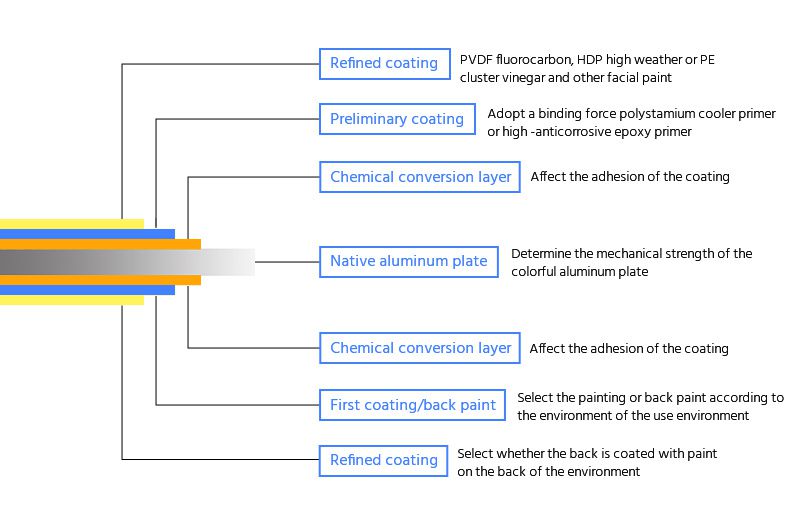

Surface treatment | PE/PVDF coated, Embossed, Mill finish, Mirror Finish, Powder coated, Wood grain, Stone grain, Checkered |

color | white series, metallic series, dark series, gold series(accept color customs), RAL/PANTONE or as color chart or customized |

Packing | Standard exporting packing/ or at buyer's requirement |

Trade Terms | FOB/CIF etc |

Diameter | 405mm, 505mm, 508mm |

Coating thickness | 14-28 microns(PE:≥14micron, PVDF:≥25micron) |

Coils core diameter | 150mm,405mm,505mm |

Temper | O - H112 |

gloss | 20-100%(matte:≥20,glossy:≥60) |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

POLYESTER | |||

Item | Technical requirements | Item | Technical requirements |

Thickness of coating film | ≥18 | Flexibility | ≤2T |

Gloss deviation | Gloss<70.Limit of error≤10% | Boiling water resistance | 2H No color change |

Hardness pf pencil | ≥2H | Color difference | △E≤2.0 |

Adhesion | ≥1Lever | MEK | ≥150 Times |

Warranty:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

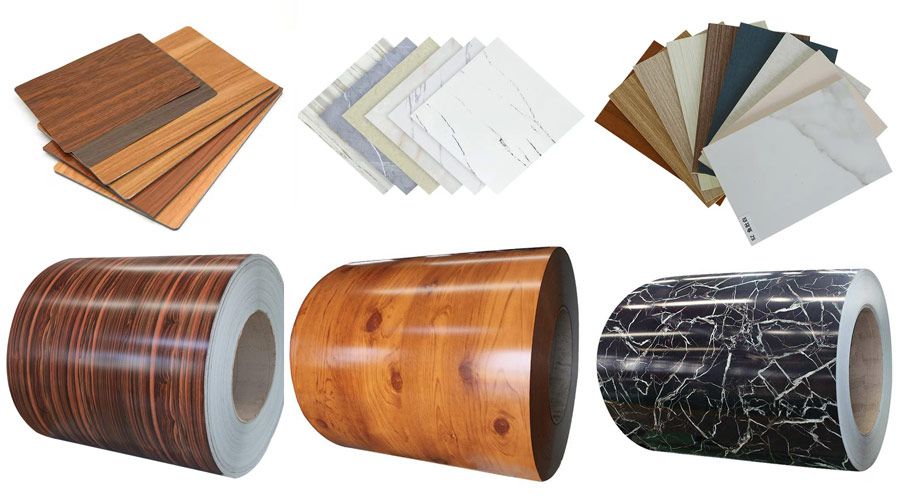

PE coated aluminum coils can be processed into a variety of different colors and textures such as metallic color, wood grain color, marble color, etc. by special surface treatment technology to meet different architectural styles and decoration requirements.

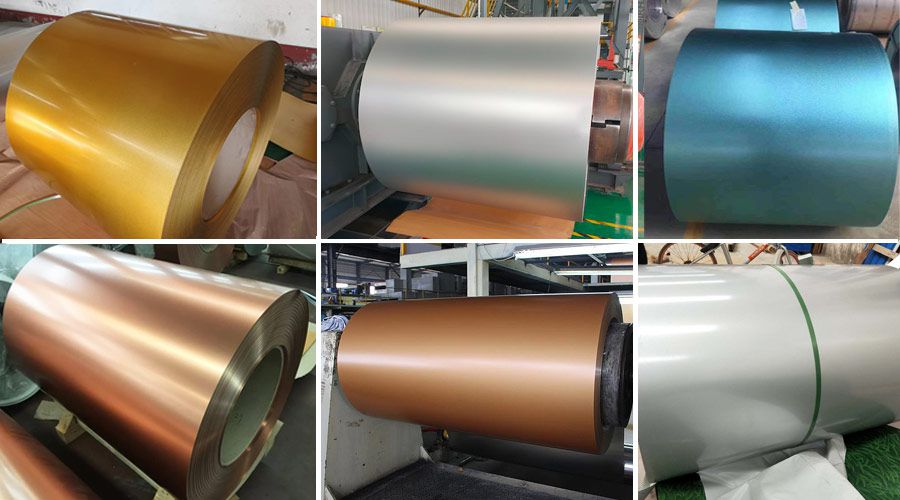

Standard Color

The standard color of coated aluminum coils is modulated according to the Ral color card. The basic colors are red, yellow, blue, green, white, gray and other colors and their derivative colors, which are suitable for most conventional applications.

Metallic Colors

The Metallic color of coated aluminum coils simulate metal textures, such as silver gray, bronze, rose gold, etc., which add a sense of luxury and class to the product and are often used in high-end architectural decoration.

Printing Series

The printing series achieve natural texture effects such as wood grain and stone grain through special coating technology, providing more diversified choices for architectural design, esuitable for places that pursue natural and environmental protection concepts.

Good Color Retention

The paint film has good color retention. Polyurethane paint has both protection and decorative properties and can be used for interior decoration coating.

Excellent Adhesion

PE paint can be formulated into an excellent adhesive. However, for metal surfaces, the adhesion of PE paint is slightly inferior to that of epoxy resin paint.

Chemical Resistance

PE coating has excellent chemical resistance, acid, alkali, salt solution, and petroleum products, so it can be used as maintenance coating for drilling platforms, ships and chemical plants.

High Temperature Resistance

PE paint can be dried at high temperature or cured at low temperature, and can also be cured normally at 0°C without being affected by the season.

PE Coated Aluminum Coil/Sheet is applied in various industries such as construction, transportation, signage, etc. It is commonly used for cladding, roofs, wall panels, panels, etc., and is favored by various industries.

Construction:

Commonly used in the production of aluminum-plastic panels, aluminum honeycomb panels, aluminum ceilings, corrugated roof panels, fire-resistant veneer panels, blinds, rolling doors, garage doors, awnings, gutters, etc.

Electronic and electrical applications:

Suitable for computer cases, electrical panels, lighting fixtures, etc.

Other applications:

Also used in furniture, solar reflectors, air conditioning ducts, and billboards, particularly for interior decoration and advertising.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)