Powder coated aluminum sheets are aluminum product that coating aluminum with a layer of powdered paint and then cured under heat to create a durable, protective finish. This process enhances the aesthetic appeal and performance of aluminum, making it a popular choice for various applications.

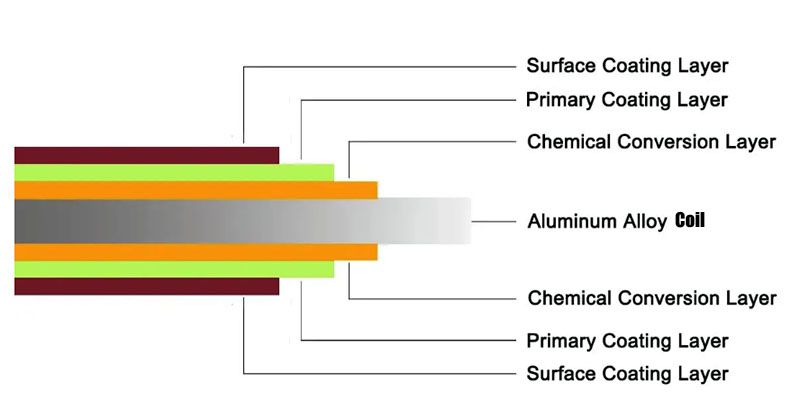

The high-performance powder coated aluminum sheet adopts the high-speed electrostatic powder coating equipment imported from France, and uses the principle of electrostatic positive and negative electricity attracting each other.It is a high-end new type of sheet formed by spraying 100% solid high-performance powder coating on the surface of the substrate and curing at a high temperature of 330 °C.

Powder coated aluminum sheet is widely used in large venues, airports and high-speed railway stations because of its good durability, light weight, and high lightness. theaters and other industries for public buildings and power plants, steel mills, chemicals, aquaculture and other industries that require high anti-corrosion performance.

Alloy | 1050, 1060, 1070, 1100, 3003, 5052, 5052, 5005, 5006, 5052, 5754, 5182 |

Thickness | 0.2-1.5mm |

Width | 600-1500mm |

Coating Surface | PVDF/ PE/HDPE/FEVE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, sheet, strips, plate |

Coil Weight | 3-8 MT |

Coil ID | 508mm and 405mm |

Certifications | ISO9001 |

Applications | Roofing System and Ceiling Decoration for Airport, Railway Stations, Exhibition Halls, Factory and Stadium |

Supply Ability | 200000 tons per year |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

Coating Options:

The choice of coating for powder coated aluminum sheets can be considered according to the needs of its application field and project cost.

- Polyester Coating: A common choice for outdoor applications due to its durability and resistance to fading.

- PVDF (Polyvinylidene Fluoride) Coating: Offers superior weathering, UV resistance, and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years;

FEVE: Three coats: 15-20 years.

Technical Data:

Coating | POLYESTER | PVDF |

Item | Technical requirements | Technical requirements |

Thickness of coating film | ≥ 18 µm | ≥ 25µm |

Gloss deviation | gloss<70, tolerance≤10% | gloss<70, tolerance≤10% |

gloss≥70, tolerance≤5% | gloss≥70, tolerance≤5% | |

Hardness of pencil | ≥3H | ≥3H |

Adhesion | no lower than class 1 | no lower than class 1 |

Flexibility | ≤2T | ≤2T |

Boiling water resistance | no change (2h) | no change (2h) |

Color difference | ΔE≤2.0 | ΔE≤2.0 |

MEK | ≥100 times | ≥150 times |

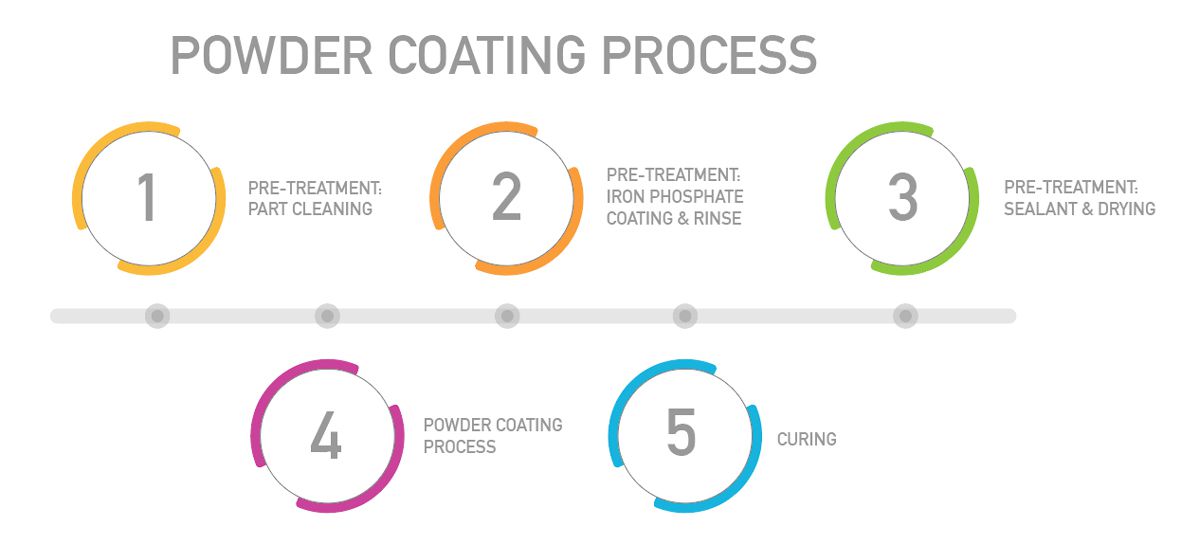

First, the powder coating is sprayed on the surface of the aluminum sheet with powder spraying equipment (electrostatic spraying machine). Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the aluminium sheet to form a powder coating;the powder coating is then baked at high temperature Leveling cures into a final coating with various effects (different kinds of effects for powder coatings).

Wear Resistance

Coating powder on the aluminum surface creates a thick layer highly resistant to wear and tear. Automotive parts treated with powder coating are known to have more excellent durability and overall strength than those coated with a conventional finishing process.

Corrosion Resistance

Powder coating can protect all sorts of items, from rough machinery to daily-use items, from heavy impact, chemicals, UV damage, and extreme weather conditions. It is naturally corrosion-resistant because of the thicker coat compared to liquid paint. This makes it ideal for parts often subject to scratches, chipping, and abrasions.

Cost-Effective

Because of its affordability, powder coating is often considered the best finishing process. As it is more durable, less maintenance is needed for re-painting and re-powdering sessions. The recyclability of overspray also reduces wastage. You won’t need to purchase any expensive pollution control equipment, as it is also more environmentally friendly.

Aesthetic

There are endless custom color options for an aesthetic finish for electronics, automotive components, and more. The powder-coated parts have a smooth finish and uniform gloss across all components.

Color Options and Texture Choices

The variety of color options makes powder coating an attractive investment. There are various options to choose from when adding color and texture. You can select a gloss, matte finish, or other options for a look you can’t achieve using liquid paint.

Environmentally Friendly

Powder coatings are environmentally friendly as they contain no solvents and barely release volatile organic compounds (VOCs) into the atmosphere. This reduces the potential costs of having to buy expensive pollution control machinery. It also helps companies comply with environmental regulations and avoid facing any penalties.

Automotive Industry

Powder coating is often used for aluminum wheels, suspension parts, roof racks, and vehicle interior and exterior trim. This method gives better corrosion protection compared to liquid paint or ceramic coating.

Aside from cars, motorbike frames and the bars and handles of buses and trains also use a powder coating.

Consumer Appliances

Thermoset powder improves the appearance of consumer appliances. This increases durability and corrosion resistance. The powder is used in dishwasher racks, freezer cabinets, the front and side panels of fridges, air-conditioner cabinets, and other similar items.

Outdoor Parts

Outdoor furniture and lawn products are also increasingly finished using this procedure. These items must resist corrosion, UV damage, and weather elements because they are unprotected out in the open. Thermoplastics are being used for this purpose as well.

Architecture

The construction and building industry often uses powder to finish frames for windows and doors, light poles, guard rails, signposts, and fences. Clear coat powders are also used on door knobs, door hinges, lamps, and plumbing fixtures and fittings.

Electronics

The durability of powder coating makes it ideal for finishing electronic components. Electroconductive and electro-dissipative powder coatings are critical during the production and distribution of electronics. They protect the components from electrostatic discharges.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)