Black aluminum sheets are aluminum product that have been coated with a black finish, typically through processes like powder coating, anodizing or painting. Black aluminium sheets are popular in various industries due to their combination of aesthetic appeal and functional properties.

Black painted aluminum sheets combine functionality, durability, and style, making them a preferred choice for various applications. Their unique properties, along with the ability to customize finishes and sizes, provide designers and engineers with the flexibility to create innovative solutions. Black color coated aluminum sheets are versatile and aesthetically appealing materials widely used in various industries, including construction, automotive, signage, and interior design.

Alloy | 1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5052, 5754, 5182, 6061, 8011 |

Thickness | 0.2-1.5mm |

Width | 30-1800mm |

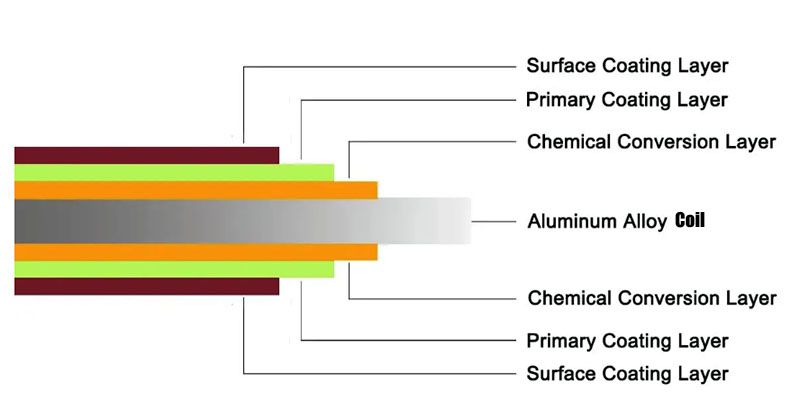

Coating Surface | PVDF/ PE/HDP/FEVE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, sheet, strips, plate |

Applications | Building, Decoration, Transportation, Signage, Electronics, Etc |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

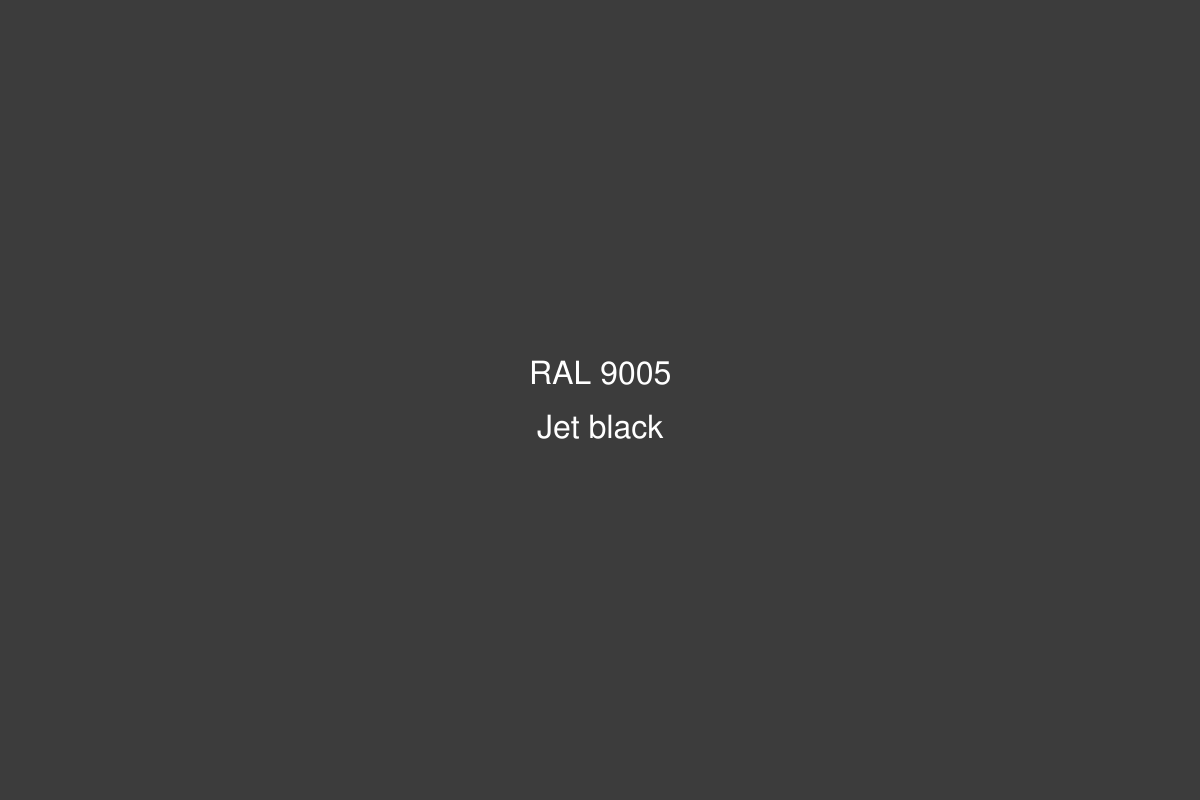

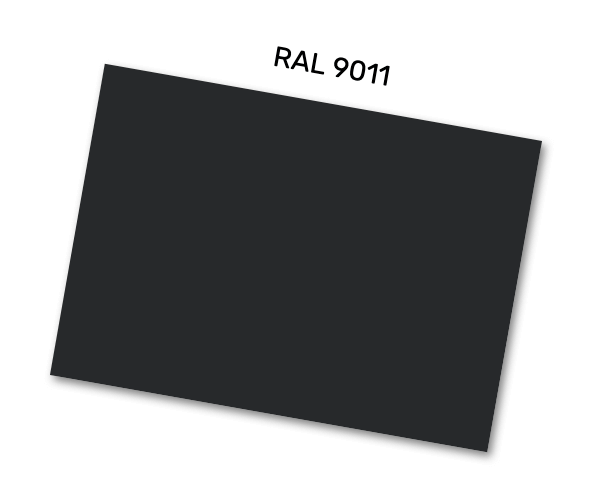

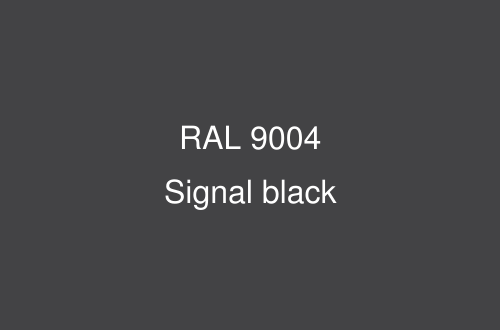

A black painted aluminum sheet is often associated with the RAL 9005 ( Jet Black or Deep Black), RAL 9011 (Graphite Black) and RAL 9004 (Signal Black).

Common RAL codes for black aluminium sheet:

RAL 9005(Jet Black or Deep Black):

This is the most common reference for a deep, jet black colour and is widely used for aluminium products.

RAL 9011 (Graphite Black):

A specific shade of black with a slightly different hue than RAL 9005.

RAL 9004 (Signal Black):

A deep, signal black that can also be found as a powder-coated colour for aluminium.

PE(Polyester) Coating:

A common choice for outdoor applications due to its durability and resistance to fading.

PVDF (Polyvinylidene Fluoride) Coating:

Offers superior weathering, UV resistance and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years

FEVE: Three coats: 15-20 years.

Aesthetic Appeal

Modern Look: The sleek black finish adds a contemporary and sophisticated appearance, making it suitable for architectural and design applications.

Versatility: The color can blend well with various design elements, allowing for creative and attractive designs.

Corrosion Resistance

Protective Coating: The coating provides an additional layer of protection against environmental factors, reducing the risk of corrosion and extending the lifespan of the material.

Durability: Coated aluminum is less prone to rust and degradation compared to untreated aluminum or other metals.

Low Maintenance

Easy to Clean: The smooth surface of coated aluminum sheets makes them easy to clean and maintain, requiring only regular washing to keep them looking new.

Stain Resistance: The coating helps resist staining and fading from UV exposure, which means less frequent replacement.

Lightweight

Ease of Handling: Aluminum is significantly lighter than other metals, making it easier to transport, handle, and install, which can reduce labor costs.

Customization

Variety of Finishes: Available in different finishes (e.g., matte, glossy, textured), allowing for customization based on specific project needs.

Cutting and Shaping: Can be easily fabricated into various shapes and sizes, making it versatile for different applications.

Environmental Benefits

Recyclability: Aluminum is highly recyclable, and the coated sheets can be recycled without losing their properties, making them an environmentally friendly option.

Cost-Effectiveness

Long-Term Savings: Although the initial cost may be higher than untreated aluminum, the durability and low maintenance requirements can lead to cost savings over time.

Fire Resistance

Non-combustible Material: Aluminum does not burn and can contribute to fire safety in building applications.

Architectural Elements:

Used in building facades, roofing, window frames, and decorative panels.

Signage:

Ideal for outdoor signs, as the coating helps resist fading and weathering.

Automotive Parts:

Commonly used for body panels, trim, and other components due to its lightweight and aesthetic qualities.

Interior Design:

Employed in furniture, wall panels, and fixtures to create a modern look.

Electrical Enclosures:

Used in housings for electronics, where aesthetics and protection are important.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)