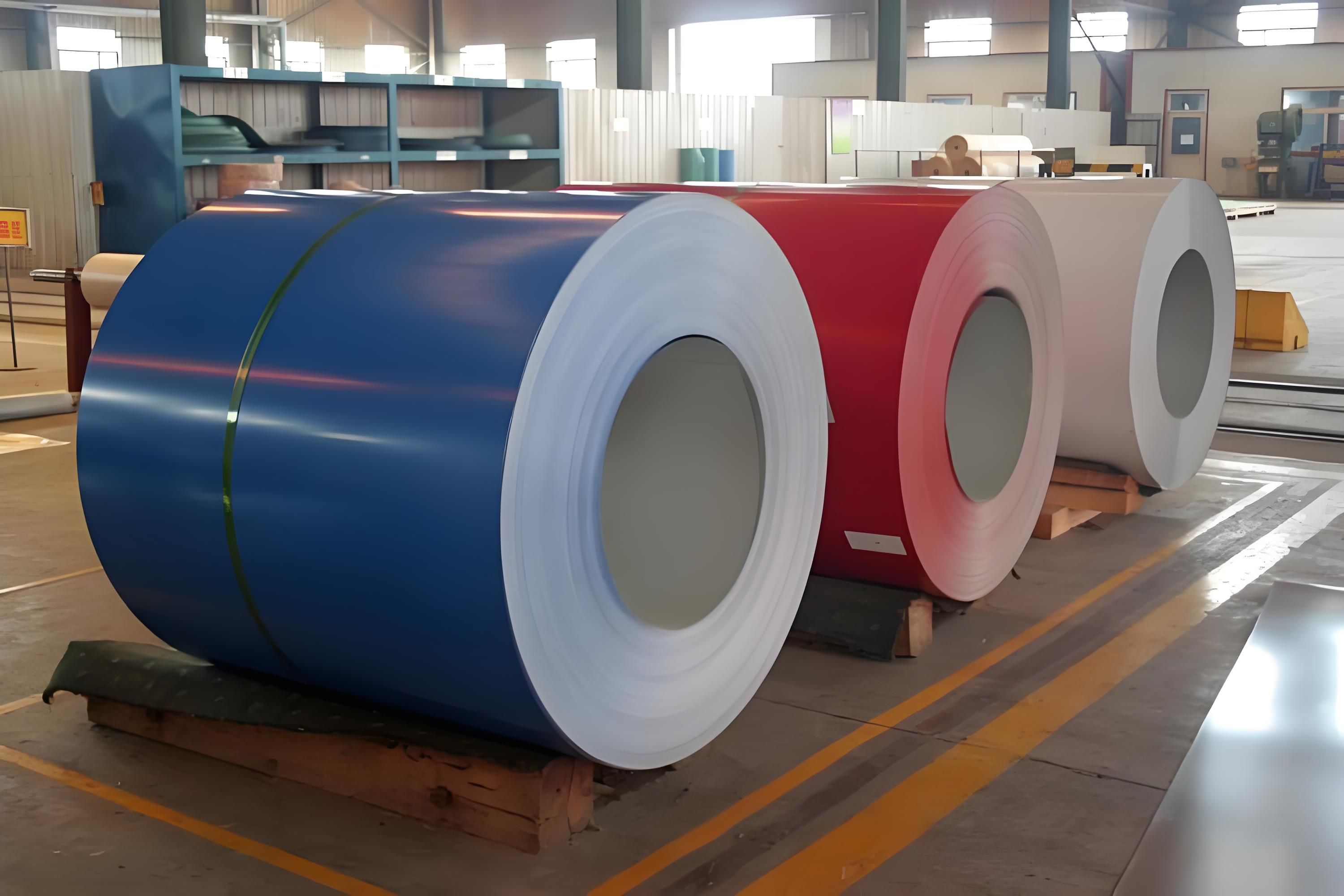

As a long time technical professional at BCM Aluminum specializing in color coated aluminum coils, this article focuses on the 3105 H26 color coated aluminum coil itself, detailing this core product that balances performance, compliance, and cost-effectiveness for partners from four dimensions: substrate characteristics, color coating process, product specifications and compliance, and core advantages.

The quality of the 3105 H26 color coated aluminum coil stems from the precise selection and strict condition control of the high-quality substrate. The substrate uses Al-Mn-Mg series 3105 aluminum alloy, with a core component of 98% high-purity aluminum, combined with 0.3-0.8% manganese, 0.2-0.8% magnesium, and trace alloying elements, ensuring product stability from the source. After cold working to the H26 temper, it achieves an excellent balance of strength and toughness without additional heat treatment: tensile strength reaches approximately 200 MPa, and elongation remains at 8%-11.5%, far exceeding the basic standards of the North American industry. It meets the needs of complex forming processes while resisting mechanical wear during long-term use, making it suitable for harsh outdoor environments and heavy-duty processing scenarios in North America.

Based on BCM Aluminum's years of metal processing experience, the 3105 coated aluminum coil adopts a proprietary high-end coating system, completely eliminating the pain points of industry homogenization. The coating uses high-quality PPG products, primarily featuring PVDF and PE coating solutions. The PVDF coating thickness is no less than 25 microns, and the PE coating thickness is no less than 18 microns, ensuring coating density. After undergoing multiple pretreatment processes, precision roller coating, and high-temperature curing, the product coating achieves a grade 0 adhesion, a pencil hardness ≥2H, and successfully passes the ASTM D-2794 impact test (50kg/cm without cracking or peeling). It exhibits MEK resistance exceeding 100 cycles, effectively resisting the strong ultraviolet radiation, rain and snow erosion, and salt spray corrosion of coastal areas in North America. Its outdoor service life can reach over 20 years, significantly reducing subsequent maintenance costs.

Targeting the actual application scenarios and compliance requirements of North American B2B customers, the 3105 H26 color coated aluminum coil has been specifically optimized, offering a complete range of specifications and meeting compliance standards. In terms of dimensions, the maximum width is up to 1250mm, and the thickness ranges from 0.5mm to 2.0mm, with tolerances precisely controlled within ±0.02mm, strictly adhering to the ASTM B209 standard. Customized sizes and a full range of RAL and PANTONE colors are also available, suitable for applications in building curtain walls, roofs, vehicle exteriors, appliance housings, and signage, among others. In terms of compliance, the product is ISO 9001 and RoHS certified, fully compliant with North American environmental regulations. Its lightweight characteristics (density only 2.7g/cm³) also help customers achieve energy conservation and emission reduction goals.

The core advantages of the 3105 H26 color coated aluminum coil are concentrated in two main aspects: stable quality and strong adaptability. On the production side, the base material is produced using a casting-rolling method, with an innovative design of a dedicated casting nozzle and magnesium ingot addition device, reducing the magnesium ingot burn-off rate to 5.11%, ensuring consistent performance across every batch. On the delivery side, leveraging BCM Aluminum's local production advantages, monthly capacity reaches 3,000 tons, with regular orders delivered within 20 days. It supports international trade terms such as FOB, CFR, and CIF, enabling rapid response to customer needs across North America, truly realizing "product adaptability to needs, quality supporting cooperation."