Brown aluminum sheets are aluminum sheets that have been coated with a brown finish, typically using painting process. Brown coated aluminum sheets offer a combination of functional benefits and aesthetic versatility, making them a popular choice in various industries.

Brown aluminum coil are used for applications like architectural panels, siding, roofing, and other decorative elements, it can be used in both residential and commercial settings due to their aesthetic appeal and durability.

Alloy | 1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5052, 5754, 5182, 6061, 8011 |

Thickness | 0.2-1.5mm |

Width | 30-1800mm |

Coating Surface | PVDF/ PE/HDPE/FEVE/EOXY/ PU |

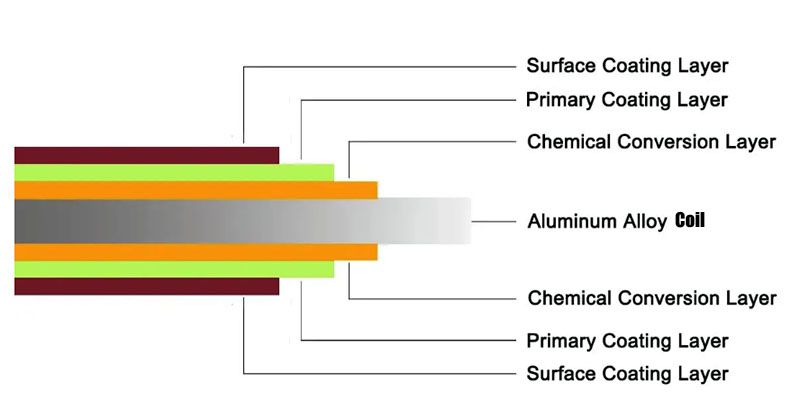

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, sheet, strips, plate |

Applications | Building, Decoration, Transportation, Signage, Electronics, Etc |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

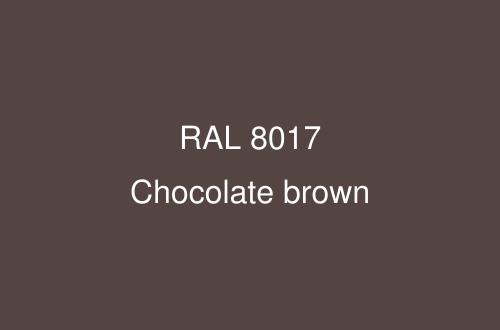

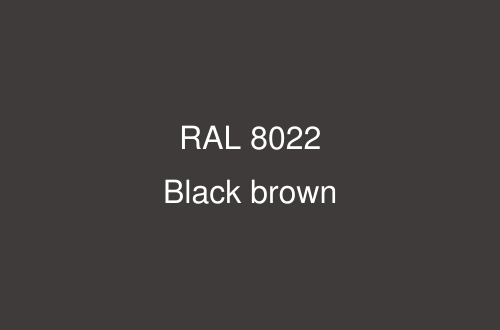

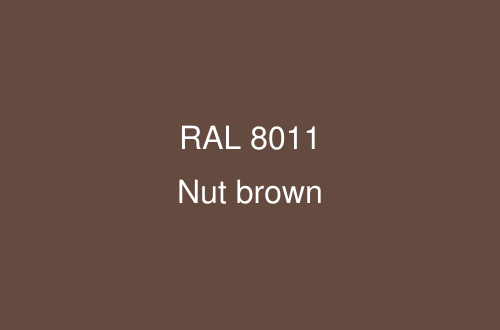

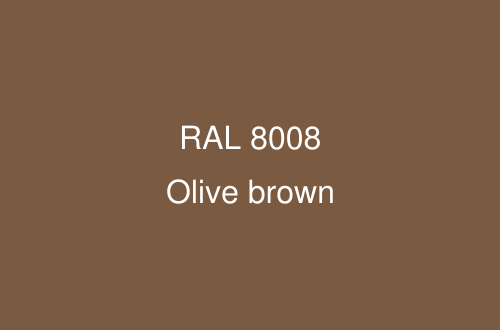

Brown coated aluminum sheets are available in various RAL codes.

RAL 8017 - Chocolate Brown

RAL 8022 - Umbra Brown

RAL 8011 - Nut Brown

RAL 8008 - Copper Brown

RAL 8014 - Sepia Brown

RAL 8024 - Beige Brown

RAL 8023 - Pearl Orange

PE(Polyester) Coating:

A common choice for outdoor applications due to its durability and resistance to fading.

PVDF (Polyvinylidene Fluoride) Coating:

Offers superior weathering, UV resistance and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years

FEVE: Three coats: 15-20 years.

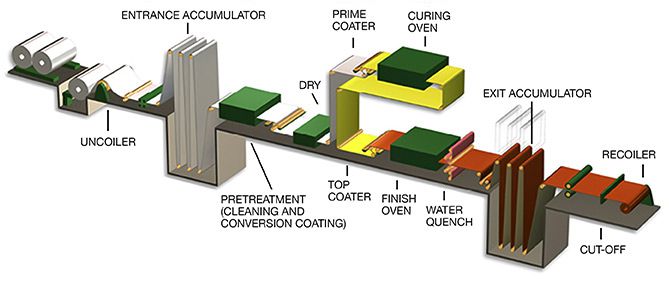

1. Surface Preparation:

The aluminum sheet is cleaned and treated to ensure proper adhesion of the coating material.

2. Primer Application:

A primer layer is applied to enhance adhesion between the aluminum substrate and the topcoat.

3. Color Coating:

The desired color or resin is applied to the primed aluminum sheet using techniques such as roller coating, spray coating, or coil coating.

4. Curing:

The brown coated aluminum sheet is then cured at high temperatures to ensure proper bonding and curing of the coating layers.

Corrosion Resistance:

Aluminum is naturally resistant to corrosion, and the coating enhances this property, making it suitable for outdoor applications.

Aesthetic Appeal:

The brown finish provides an attractive appearance, making it suitable for architectural and decorative applications.

Durability:

Coated aluminum sheets are typically more durable than bare aluminum, providing better resistance to scratches, dents, and fading over time.

Low Maintenance:

The coated surface is easier to clean and maintain compared to bare aluminum, requiring less frequent upkeep.

Lightweight:

Aluminum is a lightweight material, making it easier to handle and install compared to other metals.

Thermal Conductivity:

Aluminum has good thermal conductivity, which can be beneficial in certain applications.

Recyclability:

Aluminum is highly recyclable, making it an environmentally friendly choice.

Architectural Cladding:

Used for exterior building facades, providing both aesthetic appeal and protection.

Signage:

Ideal for outdoor signs due to its durability and weather resistance.

Roofing and Siding:

Used in residential and commercial buildings for roofing and siding applications.

Automotive Parts:

Used in vehicle components where aesthetics and weight savings are important.

Interior Design:

Used in interior applications such as wall panels, ceilings, and decorative elements.

Furniture:

Utilized in modern furniture designs for its sleek appearance and durability.

Industrial Applications:

Used in various industrial settings where lightweight and corrosion-resistant materials are required.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)