In the North American rolled aluminum products market, aluminum trim coils, with their core advantages of combining decorative and protective properties, hold a 41.6% market share, and the overall market size is projected to continue expanding at a CAGR of 8.71%. As a core product of BCM Aluminum in Canada, deeply rooted in the North American market, the brown aluminum trim coil, relying on rigorous processes and precise scene adaptation, has become a benchmark choice in residential and light commercial construction, conforming to mainstream North American aesthetics while meeting the challenges of diverse climates.

The core competitiveness of brown aluminum trim coil stems from dual control over materials and processes. We use AA 3003 aluminum alloy as the base material, adding 1.0-1.5% manganese to optimize the formula, resulting in a tensile strength of 110-180MPa, excellent bending performance, and outstanding corrosion resistance, easily coping with the harsh cold and humidity of the northeastern region and the high temperatures and intense sunlight of the southwestern region of North America. The surface utilizes a double-layer polyester baking paint process, with a front coating thickness of no less than 25μm and a back coating thickness of no less than 18μm. After high-temperature curing, the brown finish has a uniform and stable color, combining a matte texture with UV and acid/alkali resistance, boasting a service life exceeding 20 years, far surpassing industry standards.

Brown, a classic color in North American architecture, naturally complements wood structures, brick and stone facades, and metal roofs, offering exceptional versatility in application. In the residential sector, it is widely used for door and window framing, eaves fascia, and skylight flashing, effectively concealing structural gaps, preventing wood from rotting due to moisture, and enhancing the building facade's visual depth through its delicate texture. In light commercial projects, it can be processed into shop front decorative strips and public building louver frames, adapting to various design styles such as industrial and rustic, while meeting LEED green building certification requirements.

Real-world project examples further demonstrate its market value. We provided customized brown aluminum trim coils for a large residential community in the American Midwest. This project required matching the wooden siding facades and dark brown roof tiles. Considering the snowy winters in the region, we optimized the product thickness to 0.032 inches to enhance its resistance to snow pressure, while precisely matching the client's specified brown shade to ensure a unified style for the facades of over a thousand homes. Three years after project delivery, the product showed no fading, deformation, or corrosion, significantly reducing community maintenance costs and earning high praise from the general contractor. This led to subsequent collaborations on multiple residential projects in the region.

From an industry trend perspective, the demand for aluminum trim coils in the North American market is upgrading from basic protection to a more diversified demand encompassing aesthetics, functionality, and sustainability. BCM Aluminum's brown aluminum trim coils can not only be custom-shaped on-site using tools such as handbrakes to fit complex areas like doors, windows, and terrace columns, but also leverage local Canadian production advantages to shorten delivery cycles and reduce logistics costs. Compared to traditional metal trim materials, its weight is only one-third that of steel, reducing building load and aligning with the building energy conservation trend beyond automotive lightweighting.

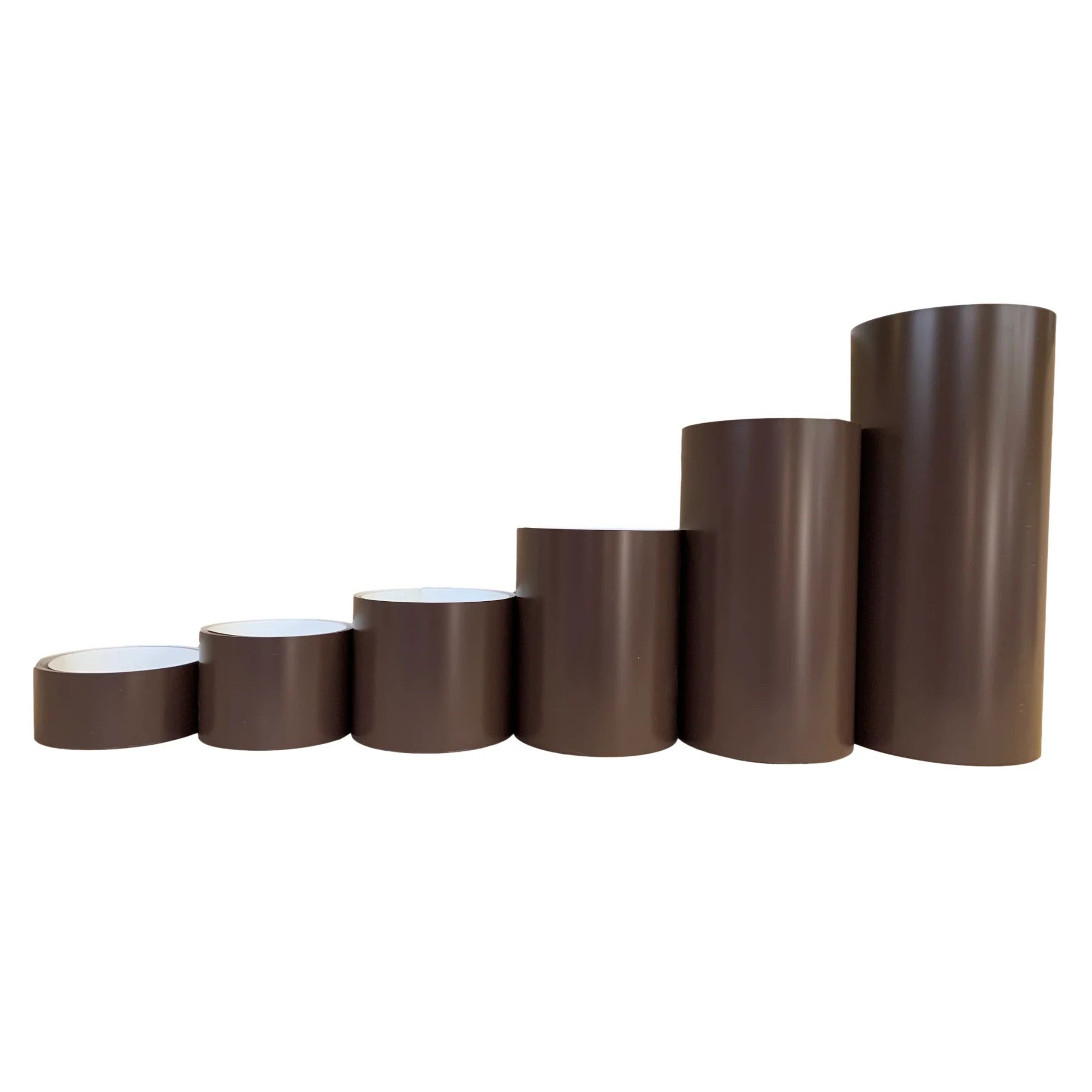

Having cultivated the North American market for many years, we deeply understand the unique needs of the region. BCM Aluminum's brown aluminum trim coils are manufactured to ASTM B209 and AAMA 2605 standards, offering a variety of sizes including 24 inches x 50 feet and 36 inches x 60 feet, flexibly adaptable to different project scales. Moving forward, we will continue to focus on upgrading coating processes and optimizing color schemes, ensuring this product maintains a balance of aesthetics, durability, and sustainability in the evolving North American construction market, creating long-term value for our customers.