1050 painted aluminum coil refers to a 1050 aluminum alloy coil that has been coated with a protective or decorative layer. It is part of the 1000 series of aluminum alloys, which are known for their excellent corrosion resistance, high thermal and electrical conductivity and good workability. The coating can enhance the material's properties, such as corrosion resistance, UV resistance, and aesthetic appeal. The 1050 aluminum alloy, as mentioned earlier, has a high purity level (99.5% aluminum), making it suitable for various applications.

Alloy | 1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5006, 5052, 5754, 5182 |

Thickness | 0.2-1.5mm |

Width | 600-1500mm |

Coating Surface | PVDF/ PE/HDPE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

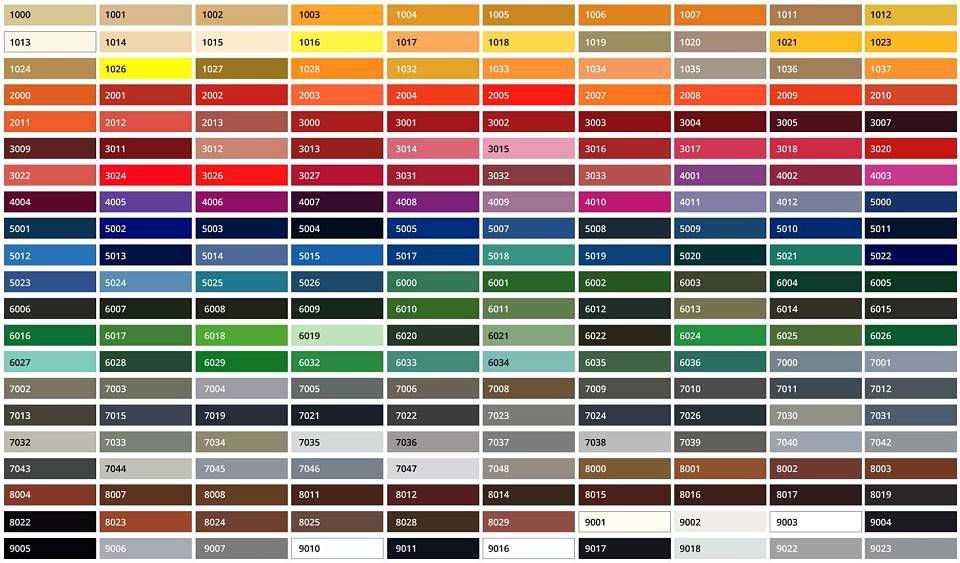

Color | All Ral Color or As Request |

Type | Coil, sheet, strips, plate |

Coil Weight | 3-8 MT |

Coil ID | 508mm and 405mm |

Certifications | ISO9001 |

Applications | Roofing System and Ceiling Decoration for Airport, Railway Stations, Exhibition Halls, Factory and Stadium |

Supply Ability | 200000 tons per year |

MOQ | 2 tons per size |

Polyester Coating: A common choice for outdoor applications due to its durability and resistance to fading.

PVDF (Polyvinylidene Fluoride) Coating: Offers superior weathering, UV resistance, and a long lifespan, often used for architectural applications.

Chemical Composition

Alloy | Si | Cu | Fe | Mg | Zn | Mn | Ti | V | Al |

1050 | 0.25 | 0.05 | 0.000~0.400 | 0.05 | 0.05 | 0.05 | 0.03 | 0.05 | 99.5 |

Mechanical Properties

Alloy & Temper | Tensile Strength(M/PA) | Yield Strength(M/PA) | Elongation(%) | Hardness(HBS) |

1050 H24 | 95~130 | 75 | 6 | / |

Physical Properties

Properties | Density | Melting Point | Thermal Conductivity | Electrical Conductivity | Thermal Expansion Coefficient |

Data | 2.7 g/cm³ | 643–657°C | 205 W/m·K | 61% IACS | 23.1×10⁻⁶/°C (20–100°C) |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

Ultra-High Purity

Reduces the risk of contamination in sensitive applications (e.g., food, pharmaceuticals).

Exceptional Formability

Ability to undergo significant deformation during manufacturing without cracking.

Cost-Effective

Lower production cost compared to higher-strength alloys due to simple processing.

Recyclability

100% recyclable with minimal property loss, supporting sustainability.

Building and Construction: Used for facades, roofing, and interior wall panels.

Electrical Applications: Cables and other components that require both conductivity and protection.

Automotive Parts: Lightweight components that benefit from corrosion resistance and aesthetics.

Signage and Displays: Durable and visually appealing surfaces for outdoor and indoor signs.

- High-Volume Production

With an annual output of 200,000 metric tons, we reliably meet the demands of large-scale projects and tight timelines.

- Global Reach, Local Presence

Our products serve clients in over 30 countries, supported by local inventory for faster delivery and support.

- Certified Quality

Our quality management system and products are certified to ISO 9001, ASTM, and CSA standards, ensuring guaranteed performance.

- Technical Expertise

Our engineering team provides expert material selection and application support to ensure optimal performance for your specific requirements.

- Full Customization

We offer complete customization of colors, finishes, and dimensions to meet exact architectural specifications.

- Sample Availability

Sample courier freight will be paid by buyer, which can be refunded after order placed, or send freely.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)

Important shipping particular will be sent to you by E-mail after delivery of the goods.

Q1. What is the minimum order quantity?

500Sqm for one color with 1220 mm*2440 mm size.

Q2. What is your terms of payment?

T/T 30% deposit in advance; the balance paid should be paid according to the copy of B/L.

Q3. How about your delivery time?

Generally, it will take 15 to 20days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings.

Q5. Why can I trust you and place order with you?

1. We are manufacture and supplier of coated aluminum sheet coil in Canada with over 10 years' experience.

2. We keep fastest delivery. Since we have perfect production equipment.