Color coated aluminum is indeed a key component in the manufacturing of aluminum composite panels (ACP).

Color coated aluminum is indeed a key component in the manufacturing of aluminum composite panels (ACP).

Color coated aluminum is indeed a key component in the manufacturing of aluminum composite panels (ACP). Providing a combination of aesthetic flexibility, durability and functional benefits.

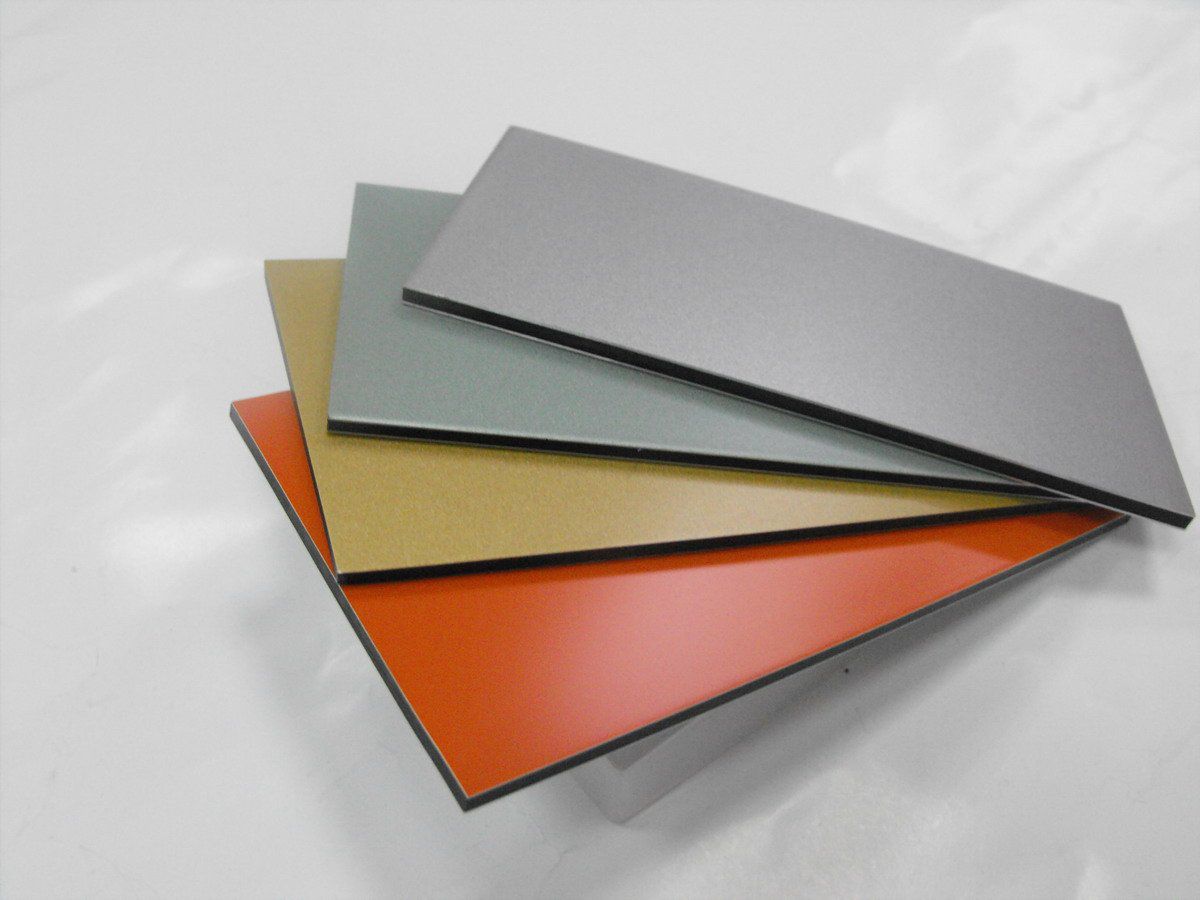

Aluminum Composite Panels are flat panels consisting of two thin layers of aluminum enclosing a non-aluminum core. The outer layers are often color coated aluminum sheets or coils, which provide both aesthetic appeal and functional benefits.

Alloy | AA1050, 1060, 1100, 3003, 3004, 3104, 3105, 5005, 5052, 6061, 8011, etc . |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.02mm to 1.5mm |

Width | Standard width 1240mm, 1270MM |

Special width 1000mm. 1200mm. 1240mm, 1270mm, 1520mm, 1620mm | |

Diameter | Standard dia: 1200mm |

Interior dia: 150mm, 405mm, 500mm, 505mm, 510mm | |

Outer diameter: 1200mm | |

Weight | 2.5 T/coil, 3.0 T/coil |

Coating thickness | PE:>=16 micron, PVDF:>=25 micron |

Protective film | As per customer's request |

Coating paint | PVDF, PE(Polyester), epoxy, polyamide, polyurethane |

Color | Solid, metallic, high gloss, stone, timber, brushed, mirror, sparkling. RAL or by customer requirements. |

Weight | As per customer's request |

Surface | Embossed, mill finish, coated |

Gloss | 10-100% |

Coating Hardness | More than 2h |

Coating adhesion | 1J |

Impact Resistance | No peeling or cracking(50 kg/cm) |

Application | ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window ,display platforms, electrical panels, etc. |

Coating Thickness | PE coating:more than 16 micron |

PVDF coating:more than 25micron |

Aesthetic Variety:

Color coated aluminum provides a wide range of colors, finishes, and textures. This allows architects and designers to achieve various aesthetic effects, making ACP suitable for modern architectural designs.

Durability:

The coating on the aluminum enhances its resistance to weathering, corrosion, and UV radiation, ensuring that the panels retain their color and finish over time. This durability is crucial for both interior and exterior applications.

Lightweight:

The use of aluminum in ACP keeps the panels lightweight, which simplifies handling and installation. This is particularly important in construction, where reducing weight can lead to lower structural support requirements.

Insulation Properties:

The core of the ACP is often made from materials like polyethylene or mineral-filled materials that provide insulation. The color-coated aluminum layers contribute to the overall thermal efficiency of the panels.

Fire Resistance:

Depending on the core material used, ACP can be designed to meet specific fire safety standards. The aluminum outer layers contribute to the panel's overall fire resistance.

Ease of Maintenance:

The smooth surface of color-coated aluminum is easy to clean and maintain. It resists dirt and grime, which is especially important for exterior applications.

Environmental Considerations:

Aluminum is a recyclable material, and the production processes for color coated aluminum can also be optimized for sustainability. This makes ACP an environmentally friendly choice in construction.

Building Facades:

ACP are widely used for cladding the exterior of buildings, providing both protection and aesthetic appeal.

Interior Walls:

They can also be used for interior applications, such as wall panels and ceilings.

Signage:

The durability and versatility of ACP make them ideal for outdoor signage and displays.

Partitioning:

ACP can be used to create lightweight and attractive partitions in commercial spaces.