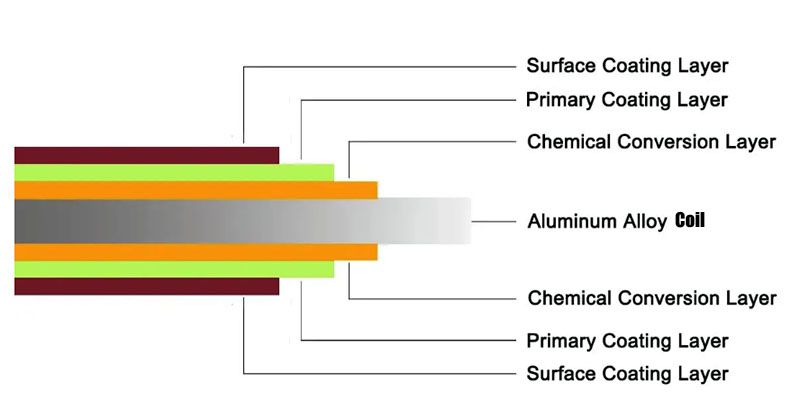

Coated aluminum sheet is a premium aluminum product with a protective and decorative layer of paint or coating applied to its surface. Known for its excellent durability, corrosion resistance, and vibrant color options, coated aluminum sheets are widely used in various industries, including construction, transportation, appliance manufacturing and signage.

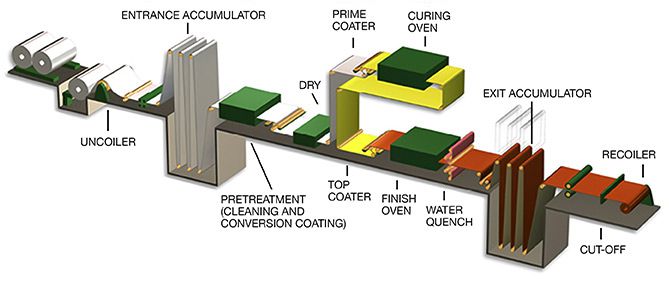

Manufactured through advanced coating technologies such as roller coating, coated aluminium sheets offer uniform color, strong adhesion, and long-lasting performance even in harsh environments. Available in a wide range of colors, finishes (matte, glossy, metallic), and thicknesses, coated aluminum sheets are ideal for applications like roofing, cladding, ceiling panels, and aluminum composite panels (ACP).

Alloy | 1050, 1060, 1070, 1100, 3003, 5052, 5052, 5005, 5006, 5052, 5754, 5182 |

Thickness | 0.2-1.5mm |

Width | 600-1500mm |

Coating Surface | PVDF/ PE/HDP/FEVE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, sheet, strips, plate |

Coil Weight | 3-8 MT |

Coil ID | 508mm and 405mm |

Certifications | ISO9001 |

Applications | Roofing System and Ceiling Decoration for Airport, Railway Stations, Exhibition Halls, Factory and Stadium |

Supply Ability | 200000 tons per year |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

The choice of coating for coated aluminum sheets can be considered according to the needs of its application field and project cost.

- Polyester Coating: A common choice for outdoor applications due to its durability and resistance to fading.

- PVDF (Polyvinylidene Fluoride) Coating: Offers superior weathering, UV resistance, and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years;

FEVE: Three coats: 15-20 years.

Technical Data:

Coating | POLYESTER | PVDF |

Item | Technical requirements | Technical requirements |

Thickness of coating film | ≥ 18 µm | ≥ 25µm |

Gloss deviation | gloss<70, tolerance≤10% | gloss<70, tolerance≤10% |

gloss≥70, tolerance≤5% | gloss≥70, tolerance≤5% | |

Hardness of pencil | ≥3H | ≥3H |

Adhesion | no lower than class 1 | no lower than class 1 |

Flexibility | ≤2T | ≤2T |

Boiling water resistance | no change (2h) | no change (2h) |

Color difference | ΔE≤2.0 | ΔE≤2.0 |

MEK | ≥100 times | ≥150 times |

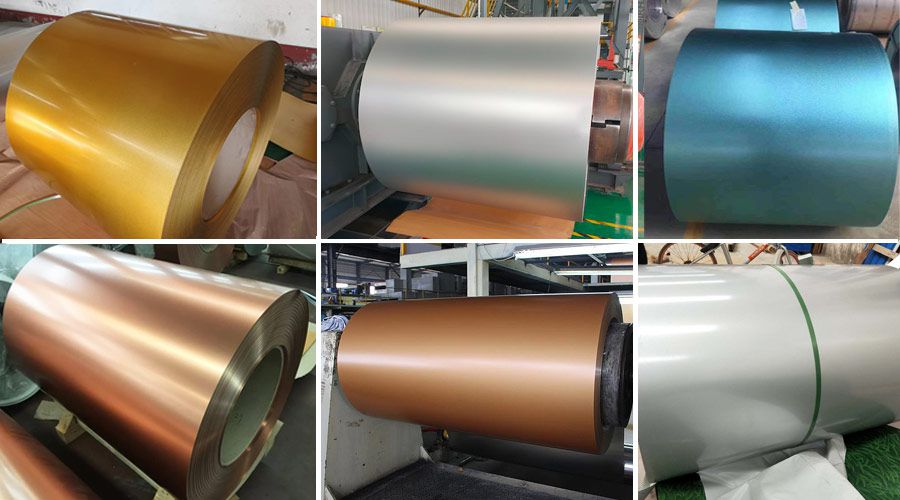

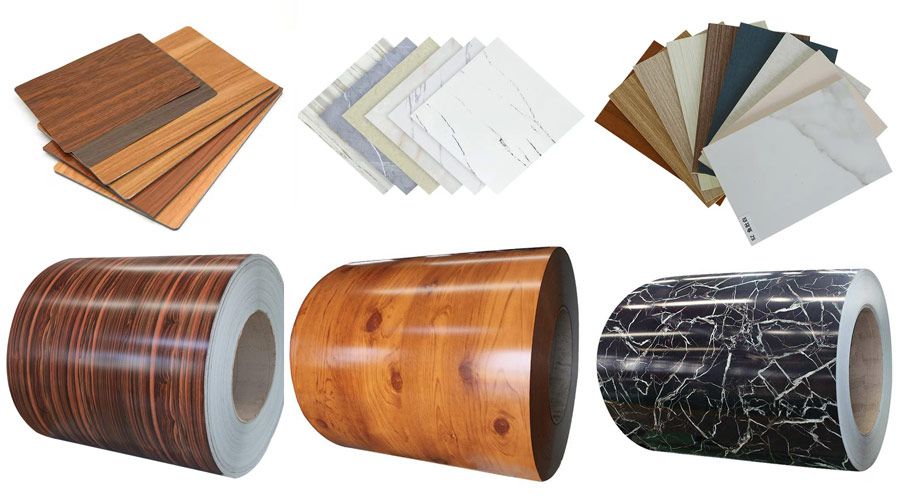

Coated aluminum sheet can be processed into a variety of different colors and textures such as metallic color, wood grain color, marble color, etc. by special surface treatment technology to meet different architectural styles and decoration requirements.

Standard Color

The standard color of coated aluminum sheets is modulated according to the Ral color card. The basic colors are red, yellow, blue, green, white, gray and other colors and their derivative colors, which are suitable for most conventional applications.

Metallic Colors

The Metallic color of coated aluminum sheets simulate metal textures, such as silver gray, bronze, rose gold, etc., which add a sense of luxury and class to the product and are often used in high-end architectural decoration.

Printing Series

The printing series achieve natural texture effects such as wood grain and stone grain through special coating technology, providing more diversified choices for architectural design, esuitable for places that pursue natural and environmental protection concepts.

Good Flatness

There is no composite high temperature indentation on the surface of the coated aluminum sheet, no residual stress on the plate surface, and no deformation after shearing.

Strong Mechanical Properties

Coated aluminum sheets will not bend, deform, or expand in harsh environments under the influence of wind pressure, temperature, humidity, and other factors.

Good Decorativeness

Coated aluminum sheets have strong coloring power and can be customized in color and pattern according to the building style. It can be coated with wood grain and marble grain to increase the beauty of the building.

Excellent Durability

Coated aluminum sheets have good durability and strong paint adhesion. Usually PE paint can be used for more than 15 years, and PVDF coating can be used for more than 30 years.

Weather Resistance

The coating of coated aluminum coils processed by roller coating and baking at high temperatures is less affected by the weather and environment, has high gloss retention, good color stability, and minimal color difference changes.

Environment-Friendly

Coated aluminum coils have good acid and alkali resistance are not easy to corrode and produce toxic bacteria, and do not release any toxic gases, which has little impact on the environment. In addition, aluminum is 100% recyclable and has high recycling value.

Because of its good durability, light weight, mild and high quality, the coated aluminium sheets is suitable for large venues, airports, high-speed railway stations and other public buildings, as well as power plants, steel mills, chemicals, aquaculture and other industries with high requirements for anti-corrosion performance.

External applications

Exterior cladding, exterior walls, roofs and canopies, tunnels, column covers or renovations

Interior applications

Wall cladding (laminate), ceilings, bathrooms, kitchens and balconies

Advertising and marketing applications

Display platforms, signboards, billboards and store fronts

Transportation and industrial applications

Manufacture of van type truck casings and cavities, car body panels, train body panels, ship car interior panels, traffic safety facility signboards,car license plate, industrial plants, radiators, air conditioners, solar reflective panels, etc.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)