Color mirror aluminum sheets are a type of aluminum that has been polished to achieve a highly reflective, mirror-like finish, combined with a color coating. This combination provides both aesthetic appeal and functional benefits, making it a popular choice in variety of design and architectural applications.

Their lightweight nature, durability, and versatility, along with the wide range of color options, allow for creative and practical uses in both commercial and residential projects.

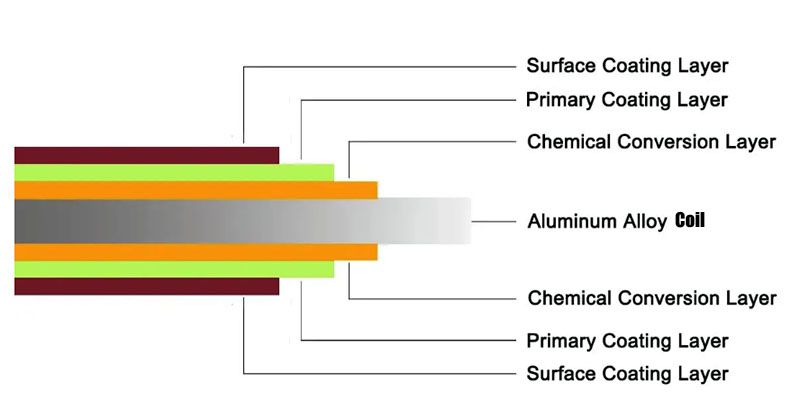

Color coated mirror aluminum sheets are aluminum sheets that have been painted with mirror paint on the basis of plain aluminum, giving them a mirror effect and color. In addition, there is also anodized color mirror aluminum sheet, which is made by anodizing the mirror aluminum sheet. Both fall into the category of color mirror aluminum sheet.

Alloy | AA1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5052, 6061, 8011, etc |

Coil thickness | 0.018-1.5mm |

Coil width | 30-2000mm, Standard 1240mm, MAX 2020mm |

Coil weight | 0.5 to 5.0 tons per coil |

Surface treatment | PE/PVDF coated, Mirror Polished |

color | Solid colors, Metallic colors |

Packing | Standard exporting packing/ or at buyer's requirement |

Trade Terms | FOB/CIF etc |

Diameter | 405mm, 505mm, 508mm |

Coating thickness | 14-28 microns(PE:≥14micron, PVDF:≥25micron) |

Coils core diameter | 150mm,405mm,505mm |

Temper | O - H112 |

gloss | 20-100%(matte:≥20,glossy:≥60) |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

Item | POLYESTER | PVDF |

Thickness of coating film | ≥ 18 µm | ≥ 25µm |

Gloss deviation | gloss<70, tolerance≤10% | gloss<70, tolerance≤10% |

gloss≥70, tolerance≤5% | gloss≥70, tolerance≤5% | |

Hardness of pencil | ≥3H | ≥3H |

Adhesion | no lower than class 1 | no lower than class 1 |

Flexibility | ≤2T | ≤2T |

Boiling water resistance | no change (2h) | no change (2h) |

Color difference | ΔE≤2.0 | ΔE≤2.0 |

MEK | ≥100 times | ≥150 times |

Warranty:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years;

FEVE: Three coats: 15-20 years.

Colors:

A wide variety of colors are available, including solid colors like orange, green, purple, and black, as well as metallic colors like titanium, copper, and dark bronze. Colors can also be customized to meet customer needs.

Surface Treatment:

In addition to color coating, anodizing can also be performed to enhance the aluminum sheet's corrosion and wear resistance. Some products also feature anti-scratch coatings for enhanced surface durability.

Aesthetic Appeal:

The mirror-like finish provides a sleek, modern look that enhances the visual impact of any project. The reflective surface can create stunning effects in both interior and exterior designs.

Variety of Colors:

Available in a wide range of colors, including solid shades, metallics, and custom options. This flexibility allows designers to achieve specific aesthetics and match branding requirements.

Lightweight:

Aluminum is significantly lighter than materials like stainless steel or glass, making it easier to handle, transport, and install. This can reduce structural load and simplify installation processes.

Durability:

The color coating provides protection against corrosion, oxidation, and wear, contributing to the longevity of the sheets. Mirror polished aluminum is also resistant to rust and can withstand various environmental conditions.

Reflective Properties:

The highly reflective surface enhances natural and artificial lighting, making spaces feel brighter and more open. This can be particularly beneficial in commercial spaces and interiors where lighting is a key design element.

Easy Maintenance:

While the polished surface may show fingerprints and smudges, it is generally easy to clean. Regular cleaning can maintain its shine and appearance, making it suitable for high-traffic areas.

Versatility:

Suitable for a wide range of applications, including architectural cladding, interior design, signage, furniture, and automotive components. Its versatility allows it to fit into various design styles and functional requirements.

Resistance to UV Rays:

The color coating can provide some level of UV protection, helping to prevent fading and degradation over time, particularly in outdoor applications.

Cost-Effective:

While the initial investment might be higher compared to standard aluminum sheets, the durability and low maintenance costs can make it a cost-effective choice in the long run.

Architectural Elements:

Used for building facades, cladding, and interior wall panels to create striking visual effects.

Signage:

Ideal for eye-catching signs and displays due to its reflective quality and vibrant color options.

Interior Design:

Commonly used in furniture, decorative accents, and fixtures to add a modern touch.

Automotive and Transportation:

Employed in vehicle design and trim for a sleek, polished appearance.

Lighting field:

As a reflector for lighting fixtures, such as reflectors for street lamps and table lamps, it can improve the light efficiency of the lamps, and its colorful appearance can also serve as a decoration.

Retail Displays:

Used in retail environments to create attractive displays that draw customer attention.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)