Prepainted aluminum sheet is aluminum that has been coated with a layer of paint or other finishes before it is formed into various products. It combines the benefits of aluminum with the aesthetic and protective qualities of paint coatings, making it a popular choice across various industries.

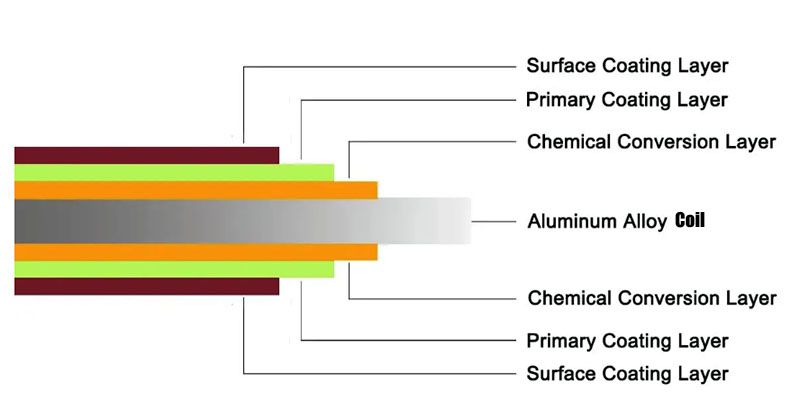

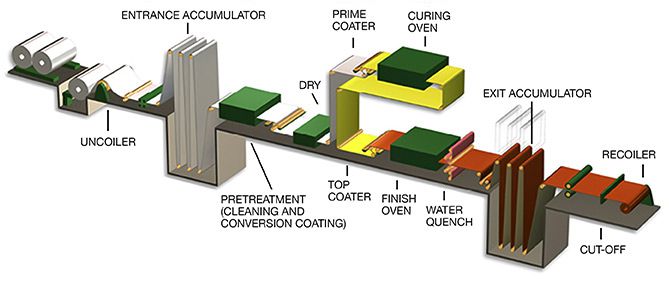

The process involves several steps, including cleaning and treating the aluminum surface, applying a primer, and then applying the final paint or coating. This pre-coating process ensures a uniform and durable finish that provides enhanced corrosion resistance, UV protection, and aesthetic appeal.

Alloy | 1050, 1060, 1070, 1100, 3003, 5052, 5052, 5005, 5006, 5052, 5754, 5182 |

Thickness | 0.2-1.5mm |

Width | 10-1800mm |

Coating Surface | PVDF/ PE/HDP/FEVE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, Sheet, Strips, Plate, Foil |

Applications | Roofing System and Ceiling Decoration |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

PE(Polyester) Coating:

A common choice for outdoor applications due to its durability and resistance to fading.

PVDF (Polyvinylidene Fluoride) Coating:

Offers superior weathering, UV resistance and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years;

FEVE: Three coats: 15-20 years.

Technical Data:

Coating | POLYESTER | PVDF |

Item | Technical requirements | Technical requirements |

Thickness of coating film | ≥ 18 µm | ≥ 25µm |

Gloss deviation | gloss<70, tolerance≤10% | gloss<70, tolerance≤10% |

gloss≥70, tolerance≤5% | gloss≥70, tolerance≤5% | |

Hardness of pencil | ≥3H | ≥3H |

Adhesion | no lower than class 1 | no lower than class 1 |

Flexibility | ≤2T | ≤2T |

Boiling water resistance | no change (2h) | no change (2h) |

Color difference | ΔE≤2.0 | ΔE≤2.0 |

MEK | ≥100 times | ≥150 times |

Standard Color

The standard color of prepainted aluminum sheet is modulated according to the Ral color card. The basic colors are red, yellow, blue, green, white, gray and other colors and their derivative colors, which are suitable for most conventional applications.

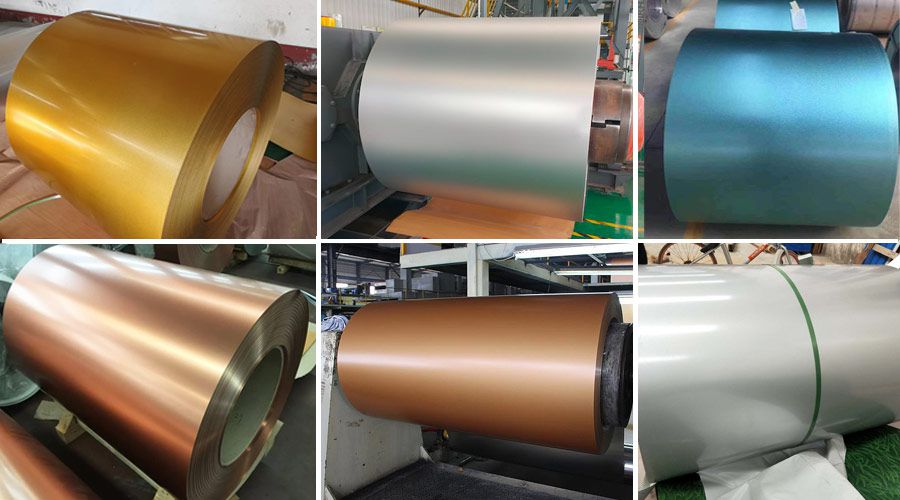

Metallic Colors

The Metallic color of prepainted aluminum sheet simulate metal textures, such as silver gray, bronze, rose gold, etc., which add a sense of luxury and class to the product and are often used in high-end architectural decoration.

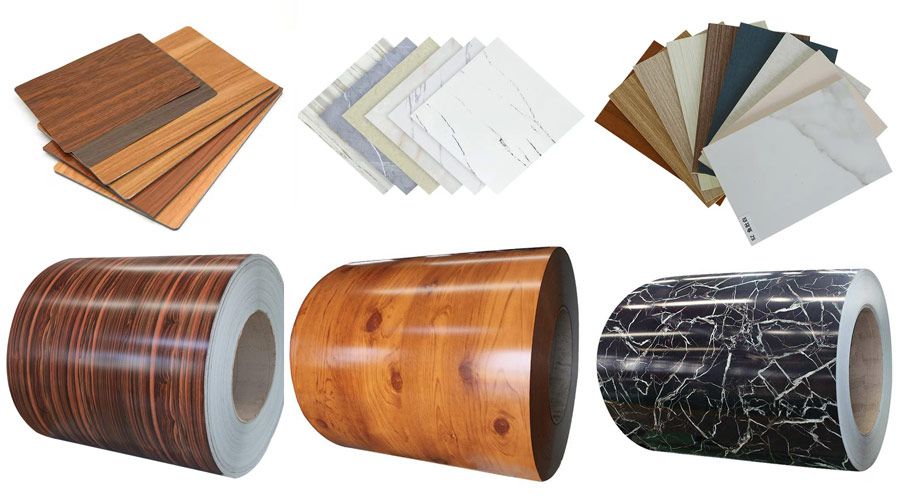

Printing Series

The printing series achieve natural texture effects such as wood grain and stone grain through special coating technology, providing more diversified choices for architectural design, esuitable for places that pursue natural and environmental protection concepts.

Corrosion Resistance

The prepainted aluminum sheet has a protective layer that shields the metal from environmental factors such as moisture, chemicals, and UV radiation. This significantly reduces the risk of rust and corrosion, making it ideal for outdoor applications and harsh environments.

Lightweight

Aluminum is approximately one-third the weight of steel, which makes it much easier to transport, handle, and install. This lightweight nature also reduces the overall structural load, which can be beneficial in construction and automotive applications.

Formability

Aluminum is a highly ductile metal, which means it can be bent, shaped, and formed into complex configurations without cracking or losing its structural integrity. This makes it suitable for applications that require intricate designs or specific shapes.

Building and Construction:

Used for siding, roofing, and other architectural applications due to its aesthetic appeal and durability.

Mobile Homes:

Commonly used in the construction of mobile homes and recreational vehicles (RVs) for its lightweight and corrosion-resistant properties.

Household Appliances:

Often used in the manufacture of appliances like refrigerators and air conditioning units, where a painted finish is desirable.

Signage:

The painted finish allows for vibrant colors and designs, making it suitable for signage and display applications.

Automotive:

Used in various automotive components and trim due to its lightweight properties and resistance to corrosion.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)