Prepainted aluminum coil is a type of aluminum sheet that has been coated with a layer of paint or other protective finishes in coil form before being fabricated into end products.

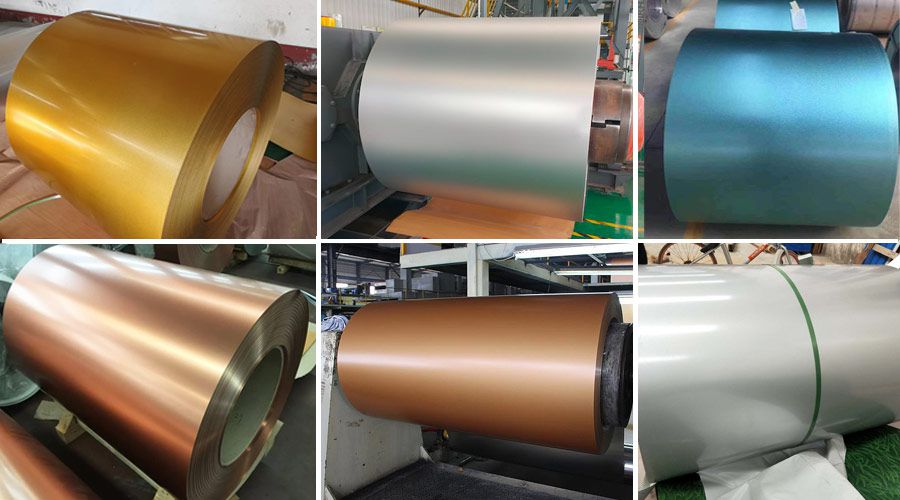

BCM’s pre-painted aluminum coils are available in a wide variety of colors, finishes and textures. They are lightweight, easy to handle, and have excellent formability, making them ideal for a variety of applications including architectural facades, roofing, cladding and more.

Alloy | 1050, 1060, 1070, 1100, 3003, 5052, 5052, 5005, 5006, 5052, 5754, 5182 |

Thickness | 0.2-1.5mm |

Width | 600-1500mm |

Coating Surface | PVDF/ PE/HDP/FEVE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, Sheet, Strips, Plate, Foil |

Applications | Roofing System and Ceiling Decoration |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

PE(Polyester) Coating:

A common choice for outdoor applications due to its durability and resistance to fading.

PVDF (Polyvinylidene Fluoride) Coating:

Offers superior weathering, UV resistance, and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years;

FEVE: Three coats: 15-20 years.

Technical Data:

Coating | POLYESTER | PVDF |

Item | Technical requirements | Technical requirements |

Thickness of coating film | ≥ 18 µm | ≥ 25µm |

Gloss deviation | gloss<70, tolerance≤10% | gloss<70, tolerance≤10% |

gloss≥70, tolerance≤5% | gloss≥70, tolerance≤5% | |

Hardness of pencil | ≥3H | ≥3H |

Adhesion | no lower than class 1 | no lower than class 1 |

Flexibility | ≤2T | ≤2T |

Boiling water resistance | no change (2h) | no change (2h) |

Color difference | ΔE≤2.0 | ΔE≤2.0 |

MEK | ≥100 times | ≥150 times |

Standard Color

The standard color of prepainted aluminum coil is modulated according to the Ral color card. The basic colors are red, yellow, blue, green, white, gray and other colors and their derivative colors, which are suitable for most conventional applications.

Metallic Colors

The Metallic color of prepainted aluminum coil simulate metal textures, such as silver gray, bronze, rose gold, etc., which add a sense of luxury and class to the product and are often used in high-end architectural decoration.

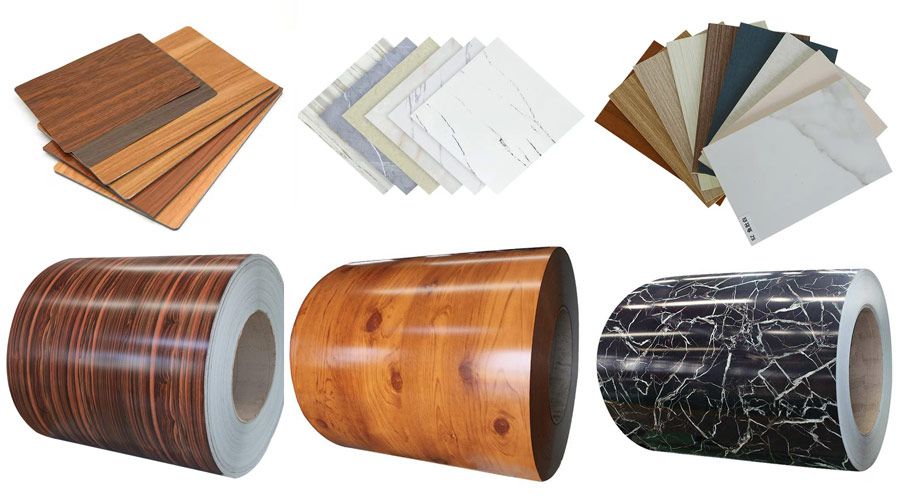

Printing Series

The printing series achieve natural texture effects such as wood grain and stone grain through special coating technology, providing more diversified choices for architectural design, esuitable for places that pursue natural and environmental protection concepts.

Model | 1000 Series Prepainted Aluminum Coil | 3000 Series Prepainted Aluminum Coil | 5000 Series Prepainted Aluminum Coil |

Main Composition | High-Purity Aluminum (≥99%) | Al-Mn Alloy | Al-Mg Alloy |

Strength | Relatively Low, Easy To Form | Medium Strength, Better Impact Resistance | High Strength, Excellent Tensile Properties |

Corrosion Resistance | Good, Suitable For General Environments | Better, Suitable For Outdoor And Humid Conditions | Excellent, Ideal For Marine And High Salt-Spray Environments |

Workability | Easy To Process, Great Ductility | Good Workability | Good Workability |

Cost | Low-Economical Option | Medium-Good Cost-Performance Ratio | Higher-For Premium Applications |

Typical Applications | Building Decoration, Packaging, Interior Use | Roofing Sheets, Wall Panels, Insulation Boards | Shipbuilding, Marine Projects, Transportation, Industrial Structures |

Surface Finish & Coating Compatibility | • Good Surface Smoothness | • Better Coating Adhesion | • Excellent Surface Stability |

Weather / UV Resistance | • Suitable For Indoor Use | • Suitable For Long-Term Outdoor Use | • Excellent For Extreme Climates |

Service Life | • Short To Medium Term | • Medium To Long Term | • Long-Lasting Durability |

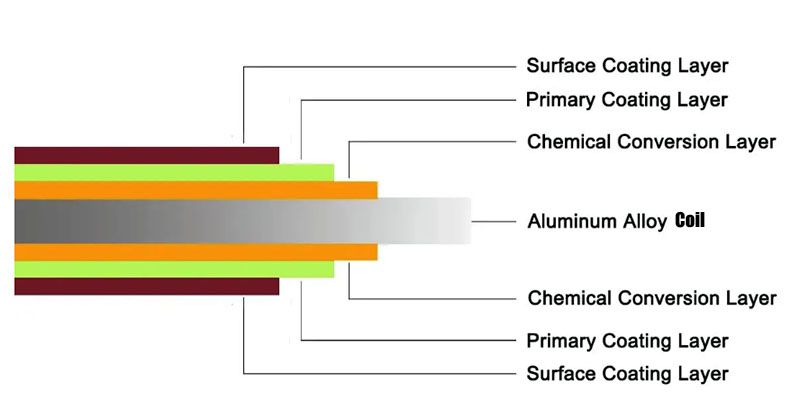

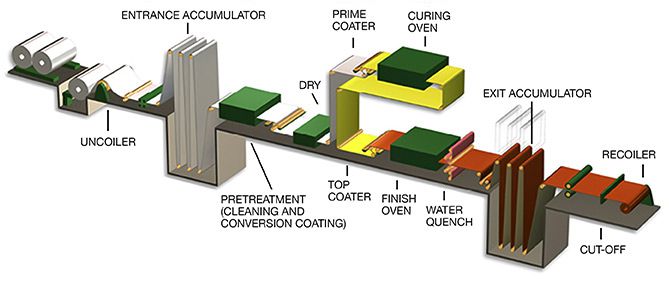

Coil coating is a continuous, automated process for coating metal before fabrication into end products. The aluminum substrate is delivered in coil form from the rolling mills. The metal coil is positioned at the beginning of the coating line, and in one continuous process, the coil is unwound, pre-cleaned, pre-treated, pre-primed, and prepainted before being recoiled on the other end and packaged for shipment.

Small Density:

The density of aluminum is only about one-third of steel. In the case of same thickness, calculate the final price on square meter basis, they are almost same.

Excellent Processability:

Due to moderate structural strength of aluminum, it's easy for processing and convenient to installation, which can reduce construction cost.

Nice Decoration:

Use aluminum for external insulation decoration, it have bright overall visual. With the addition of paint coating process, that make architectural appearance much more colorful and lively.

Long Period Of Validity:

Because of the outstanding corrosion resistance, the period of validity can reach above 25 years under normal conditions.

High Recovery:

The recovery rate can reach 85%.

Building and Construction:

Used in roofing, siding, gutters, and architectural panels.

Transportation:

Commonly used in the manufacturing of trailers, trucks, and buses.

Consumer Goods:

Found in appliances, electronic casings, and furniture.

Signage:

Used for outdoor signage due to its durability and weather resistance.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)