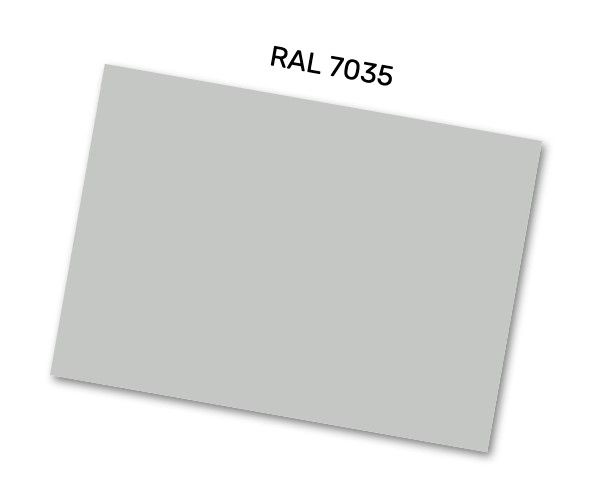

As a technical professional at BCM Aluminum, deeply involved in the North American export of color coated aluminum coils, and drawing on years of practical experience serving B2B clients in the North American construction, industrial, and home appliance sectors, I will today explain our core product—Light grey RAL 7035 aluminium coil sheet—from three dimensions: technical core, process control, and scenario adaptation. I will explain why it has become the preferred solution for neutral-colored aluminum coils in the North American market.

RAL 7035, an internationally recognized classic light gray color, belongs to the German RAL classic color card system. Its RGB values are 197, 199, and 196, with a CMYK ratio of 1:0:2:22. It presents a soft and transparent cool-toned silver-gray texture, avoiding both the heaviness and oppression of dark gray and the monotony of light gray, embodying a modern and minimalist industrial aesthetic. This is one of the core reasons why RAL 7035 grey aluminum sheet can adapt to the diverse design styles of North America. To meet the stringent requirements of North American customers for color consistency and weather resistance, we use high-purity inorganic pigments in the colorant mixing process. A precise computer-controlled color matching system controls the color difference ΔE to ≤1.0, ensuring uniform color across entire rolls and batches, completely resolving common visual discrepancies in bulk purchasing.

Technically, substrate selection is fundamental to product durability. We use mainstream 3003 and 5052 series aluminum-manganese and aluminum-magnesium alloy substrates from the North American market, with thicknesses controlled between 0.25-2.5mm and widths customizable to customer needs (up to 1700mm). The substrate undergoes a pre-stretching process to completely eliminate internal stress, ensuring it is less prone to warping, cracking, and deformation during subsequent cutting, bending, and stamping. Simultaneously, the substrate surface undergoes multiple alkaline washing, water washing, and passivation pretreatments to form a dense conversion film, significantly improving coating adhesion. Passing the ISO 2409 cross-cut adhesion test, no coating residue is left after tape application, and there are no cracks after bending at 90°.

In terms of coating technology, we balance durability and environmental friendliness, employing North American compliant PE polyester or PVDF fluorocarbon dual-coating systems, both of which have passed VOCs-free environmental certification, complying with stringent North American environmental regulations. The PE coating thickness is ≥18μm, with a weather resistance test of 3000 hours, a 10-year warranty, and excellent cost-effectiveness, suitable for indoor and general outdoor scenarios. The PVDF fluorocarbon coating thickness is ≥25μm, relying on a stable fluorocarbon bond structure, achieving a gloss retention rate of ≥80% after 1000 hours of QUV accelerated aging testing, and salt spray corrosion resistance exceeding 1000 hours, with an outdoor service life of over 20 years, particularly suitable for harsh environments such as North American coastal areas, high temperatures, and industrial pollution. All products utilize a "two-coat, two-bake" roller coating process, achieving molecular-level bonding between the coating and the substrate, resulting in excellent scratch resistance, fade resistance, and acid and alkali resistance.

Based on the actual application scenarios of North American B2B customers, we have specifically optimized RAL 7035 color coated aluminum coils. In the architectural field, its cool-toned light gray perfectly complements the curtain walls and roofs of modern office buildings and commercial complexes. It can also be used for residential ceilings and exterior wall decoration. Paired with dark gray or white lines, it creates a minimalist and sophisticated visual effect. Its lightweight nature reduces the load on building foundations, and its convenient installation reduces construction costs. In the industrial field, it can be used as a substrate for machinery housings, electrical cabinets, and server racks. Its neutral tone reduces visual fatigue and it is oil-resistant and easy to clean. In the home appliance field, it is suitable for the housings of refrigerators, air conditioners, and other appliances. Its minimalist texture aligns with North American home aesthetics, and its environmentally friendly coating meets the health standards of the home appliance industry.

As a color coated aluminum coil supplier rooted in Canada and serving North America, BCM Aluminum's core advantages lie not only in its rigorous control over product technology—each coated aluminum coil undergoes six testing checks before leaving the factory, including substrate composition, coating thickness, color difference, and adhesion—but also in its ability to provide customized technical solutions, timely logistics, and professional after-sales technical support, tailored to the purchasing habits and project needs of North American customers.

Our light gray RAL 7035 color coated aluminum coil is a core product built on technological foundations and driven by market demand. It boasts industry-leading durability and adaptability, while also reflecting our deep understanding of the needs of our North American customers. Whether you are a construction contractor, industrial equipment manufacturer, or appliance maker, BCM Aluminum will leverage its professional technical capabilities to provide you with cost-effective and highly stable color coated aluminum coil solutions, working together to achieve mutual success.