Grey coated aluminum sheets are aluminum sheets that have been treated with a grey finish, typically through processes like painting or powder coating. This finish not only enhances their aesthetic appeal but also provides several functional benefits.

Grey coated aluminum sheets are a versatile and practical choice across many industries. Their combination of aesthetic appeal, durability, and low maintenance makes them an excellent option for both functional and decorative purposes.

Alloy | 1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5052, 5754, 5182, 6061, 8011 |

Thickness | 0.2-1.5mm |

Width | 30-1800mm |

Coating Surface | PVDF/ PE/HDP/FEVE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, sheet, strips, plate |

Applications | Building, Decoration, Transportation, Signage, Electronics, Etc |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

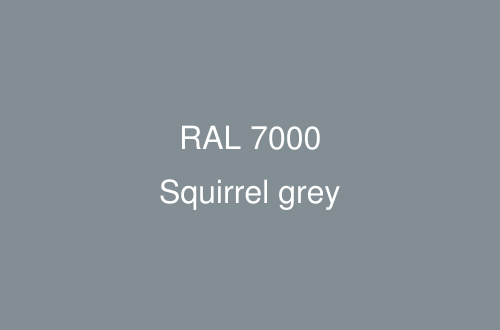

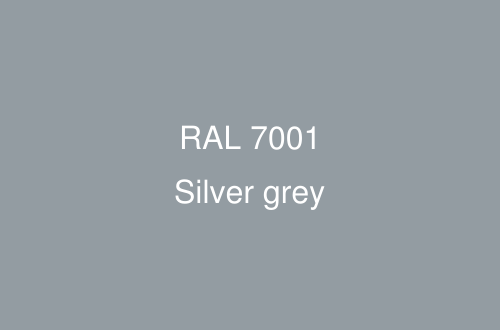

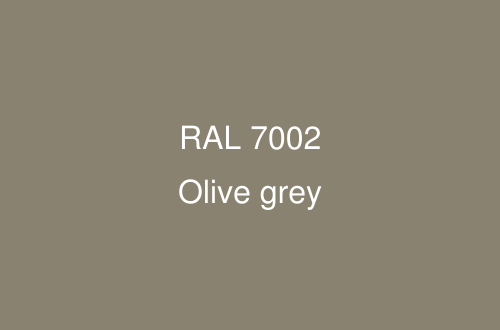

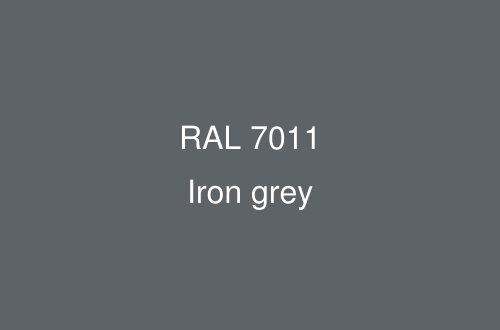

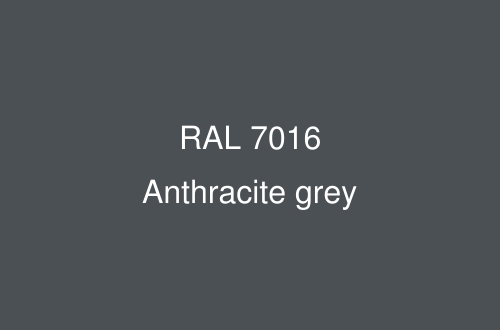

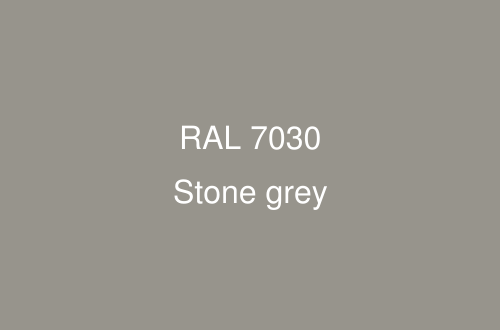

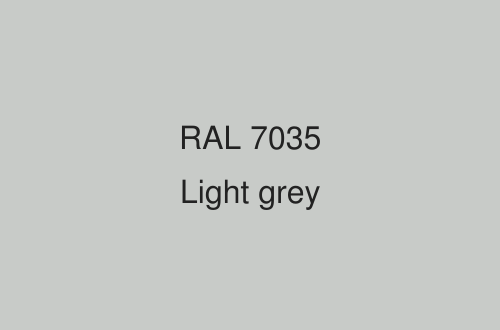

Grey coated aluminum sheets are available in various RAL codes.

RAL 7000 - Squirrel Grey

RAL 7001 - Silver Grey

RAL 7002 - Olive Grey

RAL 7011 - Iron Grey

RAL 7016 - Anthracite Grey

RAL 7030 - Stone Grey

RAL 7035 - Light Grey

PE(Polyester) Coating:

A common choice for outdoor applications due to its durability and resistance to fading.

PVDF (Polyvinylidene Fluoride) Coating:

Offers superior weathering, UV resistance and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years

FEVE: Three coats: 15-20 years.

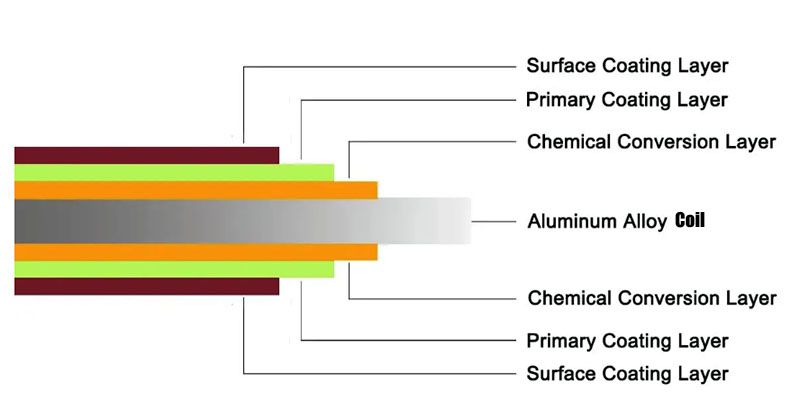

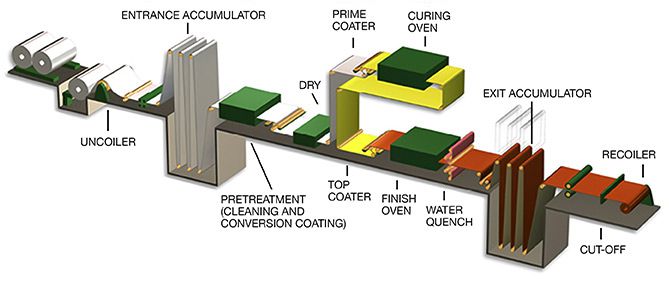

1. Surface Preparation:

The aluminum sheet is cleaned and treated to ensure proper adhesion of the coating material.

2. Primer Application:

A primer layer is applied to enhance adhesion between the aluminum substrate and the topcoat.

3. Color Coating:

The desired color or resin is applied to the primed aluminum sheet using techniques such as roller coating, spray coating, or coil coating.

4. Curing:

The grey coated aluminum sheet is then cured at high temperatures to ensure proper bonding and curing of the coating layers.

Lightweight:

Easy to handle and install.

Corrosion Resistant:

Naturally resistant to rust and degradation.

Aesthetic Appeal:

Available in various shades and finishes for a modern look.

Durability:

Scratch and wear-resistant coating for long-lasting performance.

Low Maintenance:

Easy to clean and maintain.

Versatile:

Suitable for diverse applications across industries.

Thermal Conductivity:

Good heat dissipation properties.

Recyclable:

Environmentally friendly and sustainable.

Fire Resistant:

Non-combustible, enhancing safety in building applications.

Architectural cladding:

Used for building facades, roofing, and interior panels.

Signage:

Durable and weather-resistant for outdoor signs.

Automotive:

Lightweight components that require a sleek appearance.

Furniture:

Modern and stylish finishes for various furniture pieces.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)