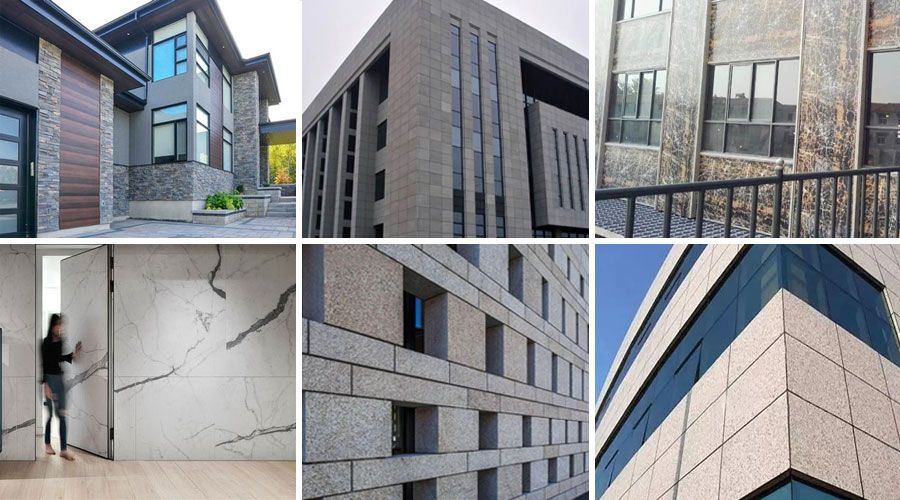

As a Canadian manufacturer of color coated aluminum sheets deeply rooted in the North American market, we understand the core material requirements of local construction – a balance between the natural texture and high-end style of granite and durability and ease of installation suitable for the diverse climates of North America. Our granite grain aluminum sheets are an upgraded product developed to meet this demand. Using high-grade aluminum alloy as the base material, and employing a core process of "nanoscale texture replication + fluorocarbon coating curing," we achieve a perfect balance between natural aesthetics and industrial performance, demonstrating irreplaceable advantages in commercial buildings and public facilities.

From a technical performance perspective, the core advantages of granite grain aluminum sheet are reflected in three dimensions.

First, its extreme weather resistance adapts to all climate zones in North America. Utilizing a fluorocarbon coating with ≥70% PVDF content, verified by QUV accelerated aging testing, after 2000 hours of UV irradiation, the color difference ΔE ≤3, and the gloss retention rate ≥60%. Even in the harsh cold of northern Canada and the strong UV environment of the southwestern United States, it ensures no fading or cracking for 20 years. The granite aluminum sheet product achieves an RC3 salt spray rating, showing no rust after 360 hours of salt spray corrosion, making it particularly suitable for construction needs in salt-spray-prone coastal areas of North America.

Secondly, it is lightweight yet high-strength, balancing safety and economy. The base material is made of 3003 series aluminum-manganese alloy with a density of only 2.7g/cm³, weighing less than one-third of natural granite, yet achieving 18J impact resistance and ≥2.5kg scratch resistance, significantly reducing the main building load. Simultaneously, the modular design increases installation efficiency by 40%, catering to the high labor costs of construction in North America.

Thirdly, it combines environmental friendliness and aesthetic appeal. The entire production process is free of hexavalent chromium and heavy metals, meeting North American environmental standards. The texture is replicated using high-definition scanning to replicate the phenocryst structure of natural granite, achieving a 98% simulation accuracy, and can be customized with various mainstream North American granite colors.

In practical applications in the North American market, granite grain aluminum sheet has already established several typical application scenarios.

In the commercial complex sector, a shopping center in California, USA, used this material for its facade. The 32,000 square meters of panels achieved a uniform texture, and after three years of use, the surface gloss retention rate still reached 85%, with cleaning costs of only 0.8 yuan/square meter per year, far lower than the 2.3 yuan/square meter per year for natural granite.

In public facilities, a rail transit hub in Ontario, Canada, chose this product for its platform ceilings. With a maximum continuous operating temperature of 100℃ and excellent acoustic adaptability, it perfectly meets the long-term usage needs of a high-traffic environment.

In the high-end residential sector, a villa project in Seattle used it to replace natural granite for its exterior walls. Each 1.2×2.4m panel weighs only 18kg, and dry-hanging installation requires no additional reinforcement, retaining the high-end texture of granite while avoiding the cracking problems of natural stone.

Compared to natural granite, granite grain color coated aluminum sheets are more in line with the North American trend of industrialized building construction. It not only solves the pain points of natural stone, such as large color variations and high transportation losses (typically over 10%), but also enables the processing of curved and irregular shapes through CNC bending, adapting to the diverse design needs of modern architecture.

As a granite grain aluminum sheet manufacturer, we can provide a full process service from texture customization to prefabrication of dimensions. Our products meet ASTM and AAMA standards, significantly shortening cross-border supply and construction cycles. Whether you are a commercial building developer, a public works contractor, or a high-end residential designer, this product, with its balanced advantages in texture, performance, and cost, is the preferred material for North American building projects.