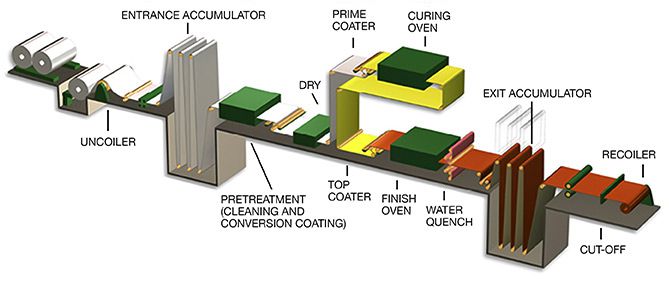

PVDF coated aluminum coil is a type of aluminum coil that has been coated with a PVDF (Polyvinylidene fluoride) paint,uses fluorinated polymer resin as the main ingredient. This highly durable, weather-resistant coating is known for its high-quality finish, excellent adhesion, and resistance to fading, chalking and cracking.

PVDF coated aluminum coil is a popular material for architectural decoration, exterior cladding, building facades, roofing systems, interior decoration and signage applications due to its vibrant colors, outstanding gloss, and long-lasting performance. PVDF paint is guaranteed about 10-15 years. It is mainly used for high-grade buildings or buildings in harsh environments, especially in chemical industry, metallurgy and other industries, as well as coastal humid areas, high UV areas and areas with serious pollution and corrosion.

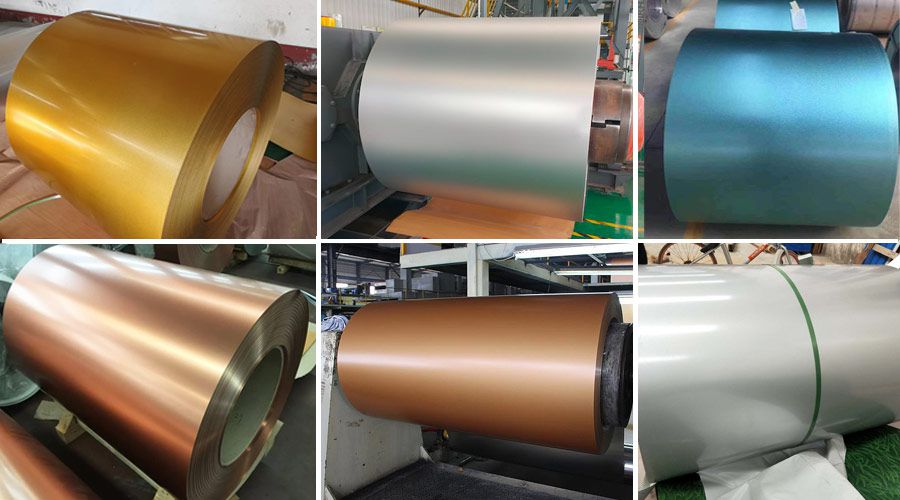

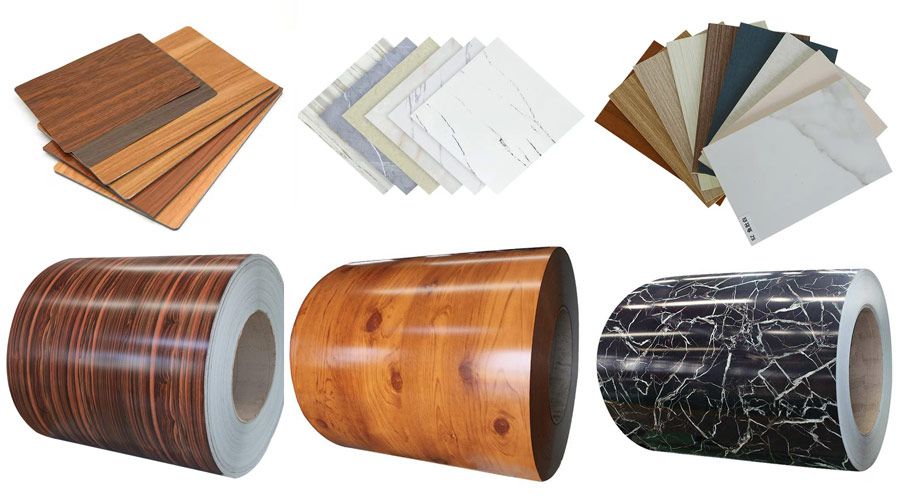

There are several types of PVDF coated aluminum coil including solid, metallic, stone and wood grain finishes. Solid finishes are the most widely used and are available in a wide range of colors. Metallic finishes give the appearance of real metal and provide a distinctive look to buildings. Stone finishes mimic natural stone, while wood grain finishes imitate the look of real wood.

Alloy | AA1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5052, 6061, 8011, etc |

Coil thickness | 0.018-1.5mm |

Coil width | 30-2000mm, Standard 1240mm, MAX 2020mm |

Coil weight | 0.5 to 5.0 tons per coil |

Surface treatment | PE/PVDF coated, Embossed, Mill finish, Mirror Finish, Powder coated, Wood grain, Stone grain, Checkered |

color | white series, metallic series, dark series, gold series(accept color customs), RAL/PANTONE color chart or customized |

Packing | Standard exporting packing/ or at buyer's requirement |

Trade Terms | FOB/CIF etc |

Diameter | 405mm, 505mm, 508mm |

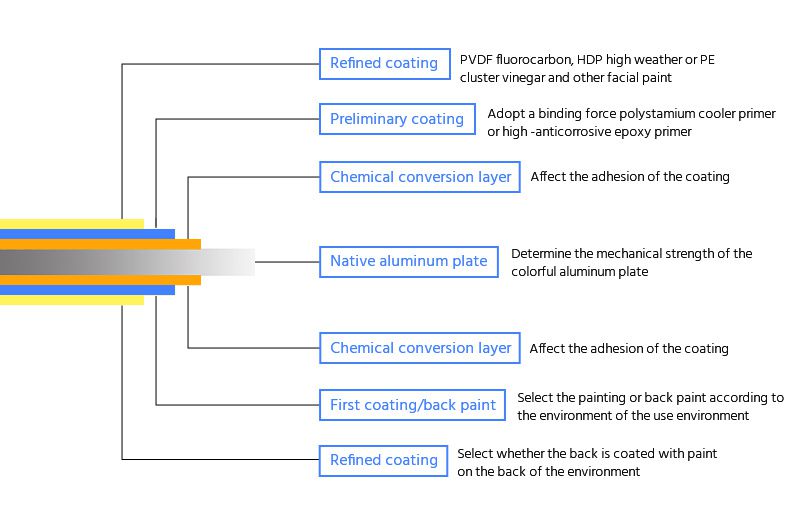

Coating thickness | 14-28 microns(PE:≥14micron, PVDF:≥25micron) |

Coils core diameter | 150mm,405mm,505mm |

Temper | O - H112 |

gloss | 20-100%(matte:≥20,glossy:≥60) |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

Traditional PVDF Coating

With KYNAR500 PVDF, two or three times for coating and baking, has good properties of anti-acid, anti-alkali and is durable in atrocious weather and environment, keeping 15 years no unwonted fading. In view of these facts, we recommend this panel applied for external wall cladding.

Nanometer PVDF Coating

Which different with traditional PVDF is the clear coating. It contains nanometer element, which can protect panel from pollution, Because nanometer has self-cleaning effect, It easy to get rid of dust and pollution by raining or water.

Property comparison between Nano-PVDF coating and PVDF coating

Coating Type | NANO Coating | PVDF Coating |

Paint Particle | 0.001micron-0.03micron | 0.3micron |

Pollution Resistance | Dust hardly sticks on the panel | Dust sticks easily |

Easy-cleaning | Dust goes away with bead | NIL |

Friction Resistance | Over 10,000 times | Several thousands times |

Acid Resistance | 5% HCI, 240 hrs | 24 hrs |

Alkali Resistance | 5% NaOH, 240 hrs | 24 hrs |

Oil Resistance | 20# machine oil, 240 hrs | 24 hrs |

Weathering | Both paints have prominent feature of weather proofing and color retention. | |

Item | Technical requirement |

Thickness of coating film | ≥25μm |

Gloss deviation | When glossiness <70, the tolerance ≤10; |

Hardness pf pencil | ≥HB |

Adhesion | ≥ grade 1 |

Flexibility | ≤2T |

Boiling water resistance | Make no difference within 2 hours |

Color difference | △E≤3.0 |

Warranty:

PVDF: 15 years;

FEVE: Two coats: between 10-15 years;

FEVE: Three coats: 15-20 years.

PVDF coated aluminum coils can be processed into a variety of different colors and textures such as metallic color, wood grain color, marble color, etc. by special surface treatment technology to meet different architectural styles and decoration requirements.

Standard Color

The standard color of PVDF coated aluminum coils is modulated according to the Ral color card. The basic colors are red, yellow, blue, green, white, gray and other colors and their derivative colors, which are suitable for most conventional applications.

Metallic Colors

The Metallic color of PVDF color coated aluminum coils simulate metal textures, such as silver gray, bronze, rose gold, etc., which add a sense of luxury and class to the product and are often used in high-end architectural decoration.

Printing Series

The printing series achieve natural texture effects such as wood grain and stone grain through special coating technology, providing more diversified choices for architectural design, esuitable for places that pursue natural and environmental protection concepts.

Durability:

PVDF coatings are known for their excellent resistance to UV radiation, weathering, and chemical exposure. This makes them suitable for outdoor applications.

Aesthetic Appeal:

The coils can be produced in a wide range of colors and finishes, allowing for versatile design options.

High Gloss and Matte Finishes:

Available in both high gloss and matte finishes, offering flexibility in design.

Easy Maintenance:

The smooth surface of PVDF coated aluminum makes it easy to clean and maintain.

Lightweight:

Aluminum is lightweight compared to other metals, making it easier to handle and install.

Longevity:

PVDF coatings can last for decades without significant fading or degradation.

Environmental Resistance:

Excellent resistance to harsh weather conditions, including extreme temperatures and humidity.

Color Stability:

Maintains color integrity over time, reducing the need for repainting or replacement.

Architectural Facades:

Used in the construction of building exteriors for both residential and commercial buildings.

Roofing:

Ideal for roofing materials due to its weather resistance.

Interior Design:

Can be used for interior wall panels, ceilings, and decorative elements.

Signage:

Suitable for outdoor signage due to its durability and color retention.

Automotive and Transportation:

Sometimes used in vehicles for aesthetic and protective purposes.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)