Blue aluminum sheets are aluminum sheets that have been finished or coated with a blue color. Combines the physical properties of aluminum sheet with the decorative and protective functions of the coating. Blue aluminium sheets are utilized in various applications due to their lightweight nature, durability and aesthetic appeal.

Blue offers a rich palette of shades, customizable according to RAL, Pantone, or other color charts, or based on client samples. It adds a distinctive visual appeal to architecture, appliances, and more, creating a serene and professional ambiance.

Alloy | 1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5052, 5754, 5182, 6061, 8011 |

Thickness | 0.2-1.5mm |

Width | 30-1800mm |

Coating Surface | PVDF/ PE/HDPE/FEVE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, sheet, strips, plate |

Applications | Building, Decoration, Transportation, Signage, Electronics, Etc |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

Blue coated aluminum sheets are available in various RAL codes.

RAL 5002 - Ultramarine Blue

RAL 5010 - Gentian Blue

RAL 5015 - Sky Blue

RAL 5011 - Steel Blue

RAL 5005 - Signal Blue

PE(Polyester) Coating:

A common choice for outdoor applications due to its durability and resistance to fading.

PVDF (Polyvinylidene Fluoride) Coating:

Offers superior weathering, UV resistance and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years

FEVE: Three coats: 15-20 years.

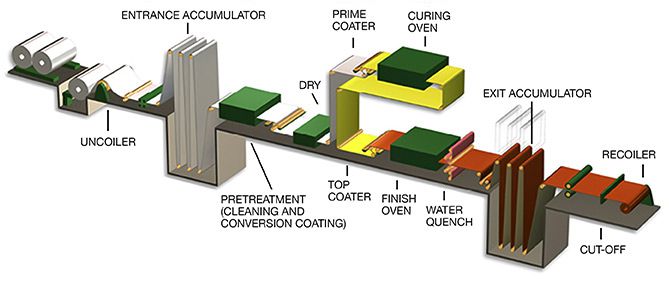

1. Surface Preparation:

The aluminum sheet is cleaned and treated to ensure proper adhesion of the coating material.

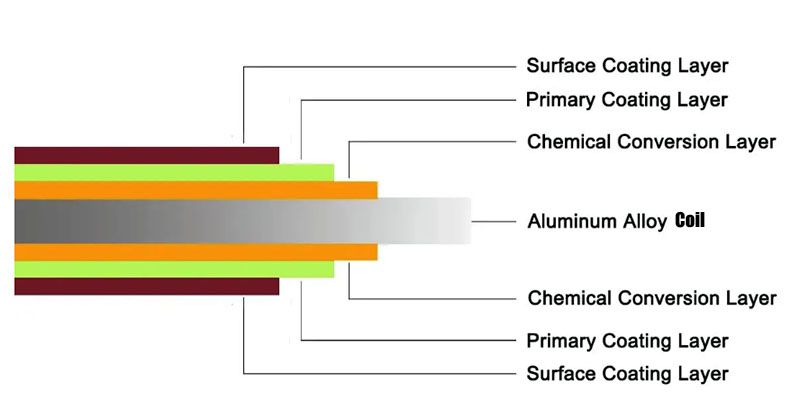

2. Primer Application:

A primer layer is applied to enhance adhesion between the aluminum substrate and the topcoat.

3. Color Coating:

The desired color or resin is applied to the primed aluminum sheet using techniques such as roller coating, spray coating, or coil coating.

4. Curing:

The blue coated aluminum sheet is then cured at high temperatures to ensure proper bonding and curing of the coating layers.

Corrosion Resistance:

Aluminum is naturally resistant to corrosion, and the coating adds an extra layer of protection.

Aesthetic Appeal:

The blue finish provides a modern and attractive look, suitable for various design styles.

Durability:

Coated aluminum sheets have a long lifespan and can withstand harsh environmental conditions.

Lightweight:

Aluminum is lighter than many metals, making it easier to handle and install.

Low Maintenance:

The coated surface is easy to clean and requires minimal maintenance over time.

Versatility:

Can be used in a variety of applications, from industrial to decorative.

Architectural Panels:

Used in building facades, cladding, and roofing materials for aesthetic appeal.

Interior Design:

Commonly used in wall panels, ceilings, and decorative elements in commercial and residential buildings.

Signage:

Blue coated aluminum sheets are often used for outdoor signage and displays due to their weather resistance.

Transportation:

Used in vehicle bodies, trailers, and marine applications where weight and corrosion resistance are important.

Furniture:

Can be used in modern furniture designs for tables, chairs, and cabinetry.

Electronics:

Used in housings and enclosures for electronic devices due to its durability and aesthetic quality.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)