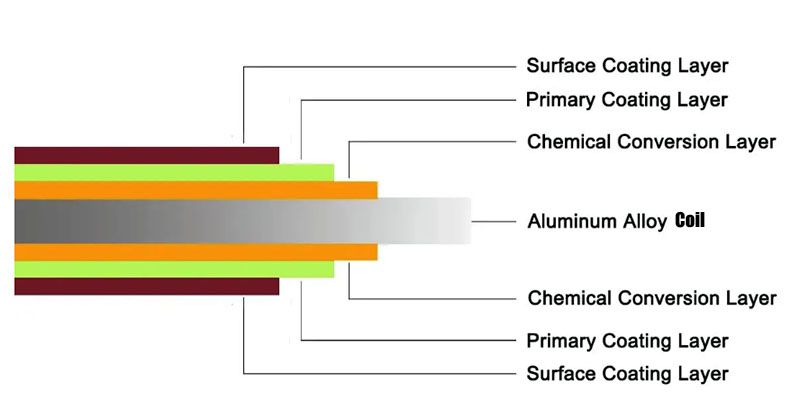

Coated aluminum coils are made of aluminum alloy sheet that have been surface treated and painted at high temperature. Color coated aluminum coils have good corrosion resistance and decorative properties. Coated aluminum coils are widely used in building materials because of their light material, high strength, rust resistance, fire resistance, moisture resistance, mildew resistance and good decorative properties.

Alloy | 1050, 1060, 1070, 1100, 3003, 5052, 5052, 5005, 5006, 5052, 5754, 5182 |

Thickness | 0.2-1.5mm |

Width | 600-1500mm |

Coating Surface | PVDF/ PE/HDP/FEVE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, sheet, strips, plate |

Coil Weight | 3-8 MT |

Coil ID | 508mm and 405mm |

Certifications | ISO9001 |

Applications | Roofing System and Ceiling Decoration for Airport, Railway Stations, Exhibition Halls, Factory and Stadium |

Supply Ability | 200000 tons per year |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

The choice of coating for coated aluminum coils can be considered according to the needs of its application field and project cost.

- Polyester Coating: A common choice for outdoor applications due to its durability and resistance to fading.

- PVDF (Polyvinylidene Fluoride) Coating: Offers superior weathering, UV resistance, and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years;

FEVE: Three coats: 15-20 years.

Technical Data:

Coating | POLYESTER | PVDF |

Item | Technical requirements | Technical requirements |

Thickness of coating film | ≥ 18 µm | ≥ 25µm |

Gloss deviation | gloss<70, tolerance≤10% | gloss<70, tolerance≤10% |

gloss≥70, tolerance≤5% | gloss≥70, tolerance≤5% | |

Hardness of pencil | ≥3H | ≥3H |

Adhesion | no lower than class 1 | no lower than class 1 |

Flexibility | ≤2T | ≤2T |

Boiling water resistance | no change (2h) | no change (2h) |

Color difference | ΔE≤2.0 | ΔE≤2.0 |

MEK | ≥100 times | ≥150 times |

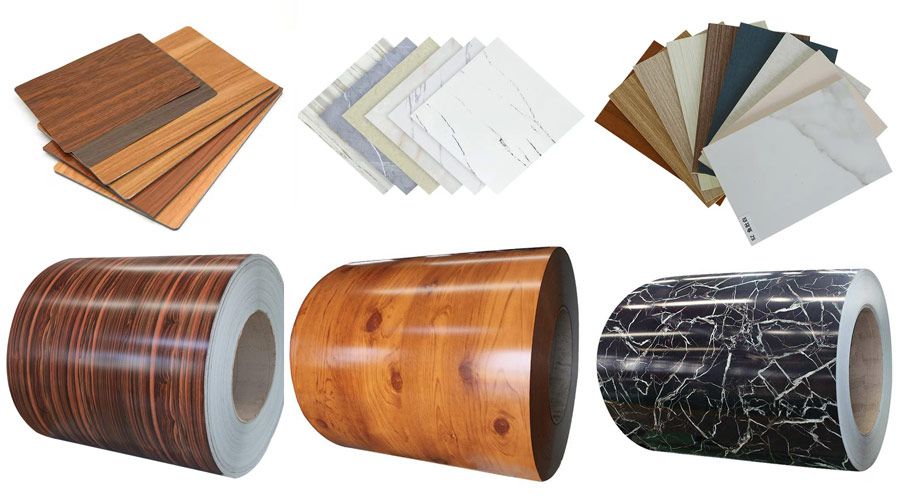

Coated aluminum coils can be processed into a variety of different colors and textures such as metallic color, wood grain color, marble color, etc. by special surface treatment technology to meet different architectural styles and decoration requirements.

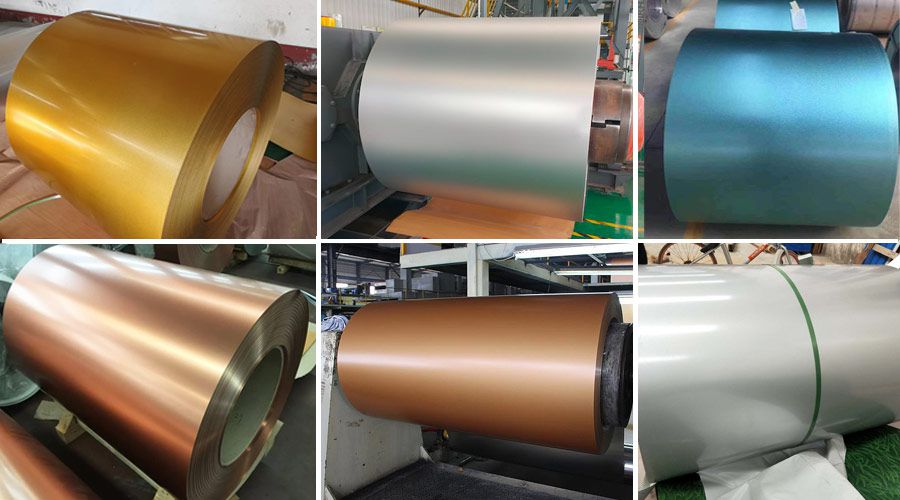

Standard Color

The standard color of coated aluminum coils is modulated according to the Ral color card. The basic colors are red, yellow, blue, green, white, gray and other colors and their derivative colors, which are suitable for most conventional applications.

Metallic Colors

The Metallic color of coated aluminum coils simulate metal textures, such as silver gray, bronze, rose gold, etc., which add a sense of luxury and class to the product and are often used in high-end architectural decoration.

Printing Series

The printing series achieve natural texture effects such as wood grain and stone grain through special coating technology, providing more diversified choices for architectural design, esuitable for places that pursue natural and environmental protection concepts.

Model | 1000 Series Coated Aluminum Coil | 3000 Series Coated Aluminum Coil | 5000 Series Coated Aluminum Coil |

Main Composition | High-Purity Aluminum (≥99%) | Al-Mn Alloy | Al-Mg Alloy |

Strength | Relatively Low, Easy To Form | Medium Strength, Better Impact Resistance | High Strength, Excellent Tensile Properties |

Corrosion Resistance | Good, Suitable For General Environments | Better, Suitable For Outdoor And Humid Conditions | Excellent, Ideal For Marine And High Salt-Spray Environments |

Workability | Easy To Process, Great Ductility | Good Workability | Good Workability |

Cost | Low-Economical Option | Medium-Good Cost-Performance Ratio | Higher-For Premium Applications |

Typical Applications | Building Decoration, Packaging, Interior Use | Roofing Sheets, Wall Panels, Insulation Boards | Shipbuilding, Marine Projects, Transportation, Industrial Structures |

Surface Finish & Coating Compatibility | • Good Surface Smoothness | • Better Coating Adhesion | • Excellent Surface Stability |

Weather / UV Resistance | • Suitable For Indoor Use | • Suitable For Long-Term Outdoor Use | • Excellent For Extreme Climates |

Service Life | • Short To Medium Term | • Medium To Long Term | • Long-Lasting Durability |

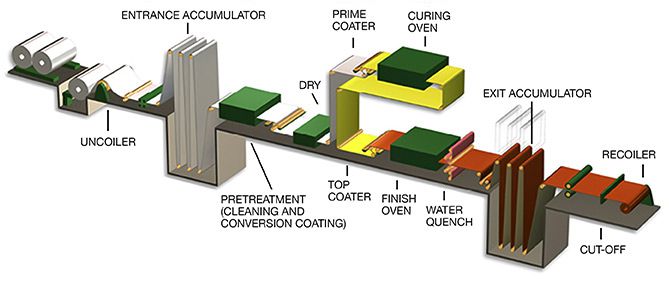

Coil coating is a continuous, automated process for coating metal before fabrication into end products. The steel or aluminum substrate is delivered in coil form from the rolling mills. The metal coil is positioned at the beginning of the coating line, and in one continuous process, the coil is unwound, pre-cleaned, pre-treated, pre-primed, and prepainted before being recoiled on the other end and packaged for shipment.

High Durability: Our coated aluminum coils are corrosion-resistant, ensuring a longer lifespan.

Aesthetic Appeal: The wide range of colors and finishes enhances the visual appeal of your products.

Environmental Friendly: Our products are eco-friendly and can be recycled.

Easy Maintenance: Minimal maintenance is required to keep the coils in top condition.

- Customization: We offer customized solutions to meet specific project requirements.

Architectural Cladding

We use aluminium coils with PVDF coating mostly for creating walls and buildings. The covering makes the aluminium better against different weather conditions. It stops damage caused by the outside environment.

Roofing Systems

Select high-quality aluminium with PVDF coating that is robust and provides high UV resistance to be used in roofing construction. They are ideal in outdoor applications, guarantee durable service, and assure safety and strength on built structures.

Signage and Display Panels

Known for creating great signs and show boards, coated aluminum coil are very unique. The paint makes them look better, blending light and strong toughness. This is what makes them special since no one can do it as well as they can do it.

Exterior Curtain Walls

In contemporary architecture, exterior curtain walls made out of coated aluminum coil are common. This guard shield offers protection to the building, maintaining the beauty it needs and hence surviving the elements and weathering.

Interior Wall Panels

Frequently deployed in outdoor applications, coated aluminum coil are just as apt to be applied on interior projects. They are strong and highly finished to produce lovely walls that match different home contents and architectural designs.

Ceiling Panels

Aluminium finished with PE/PVDF coating are perfectly used as panels on ceilings in residential and business buildings. They have a special finish that prevents soiling and fading to keep their beauty long-lasting and with minimal maintenance.

Furniture Components

Aluminium sheets coated with PVDF are good enough and are light to carry, and do not demand much strain. This ensures that they can be applied in the manufacture of furniture to be used either outdoors or indoors, and still be appealing to the eyes.

Electronic Appliances

Due to their excellent property of corrosion protection, coated aluminum coil are widely used in the sectors of electronics and household appliances. They are practical, but good-looking, and have functionality and good looks fused.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)

minum