At BCM, our state-of-the-art manufacturing facility is the engine behind every meter of premium coated aluminum we produce. We've invested in advanced technology and rigorous processes to ensure that our products not only meet but exceed the demanding standards of the North American construction industry.

Precision Manufacturing & Advanced Equipment

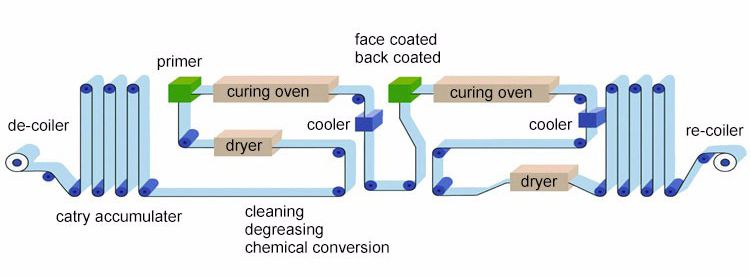

Our sprawling production complex houses fully automated, high-speed coil coating lines. Utilizing cutting-edge technology from world-leading suppliers, we achieve flawless and consistent application of PVDF (Kynar 500®/Hylar 5000®) and PE coatings. This precision engineering guarantees superior surface finish, exact color matching, and exceptional material performance for every order, large or small.

Uncompromising Quality Control

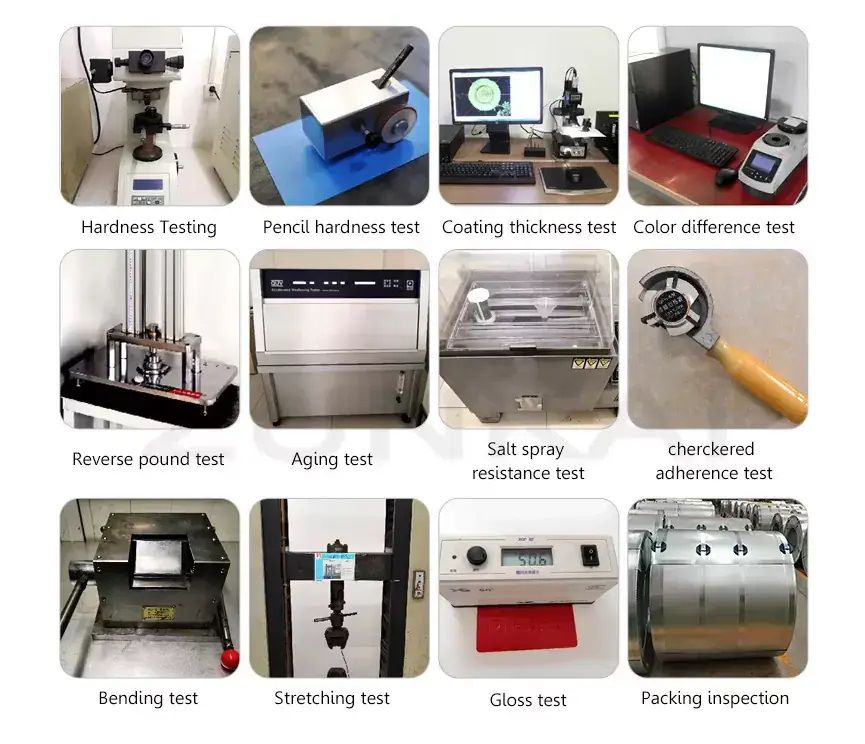

Quality is not just a step in our process; it's embedded in every stage. From incoming raw material inspection to final shipment, our dedicated QC team performs a multi-point check:

Coating Thickness: Measured to exact mil specifications.

Adhesion & Hardness: Tested to prevent peeling and scratching.

Color Consistency: Spectrophotometer-verified for perfect batch-to-batch matching.

Performance Validation: Rigorous salt spray testing, UV resistance, and weather ability checks to ensure longevity in harsh Canadian climates. Our compliance with ASTM and CSA standards is certified and verifiable.

Strategic Inventory & Logistics

Understanding the critical importance of timelines in construction, we maintain a significant ready-to-ship inventory of popular colors and gauges at our Canadian warehouse facilities. This strategic stock, combined with our efficient logistics network, allows us to offer reliable lead times and just-in-time delivery.

Our commitment is to be more than a supplier, we are your trusted partner, providing the material certainty you need to build with confidence!