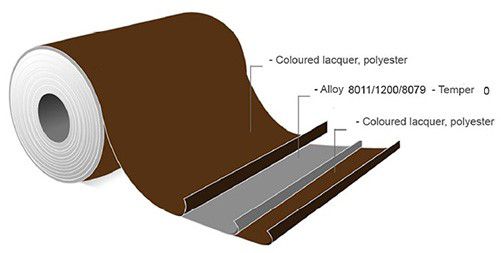

Color Coated Aluminum Foil is a high-performance aluminum foil with a specialized coating treatment that offers excellent weather resistance, corrosion resistance and thermal insulation properties. Color coated aluminum foil is commonly used for building insulation, roof and wall decoration. Its moisture-proof, airtight and light-shielding properties can effectively improve building energy efficiency.

Lacquered or color coated aluminum foil with coatings like PE, PVDF, and Fluorocarbon offers excellent durability, thermal insulation, and weather resistance. It is widely used in building insulation, roof waterproofing, and indoor thermal insulation applications, providing customers with durable and efficient solutions.

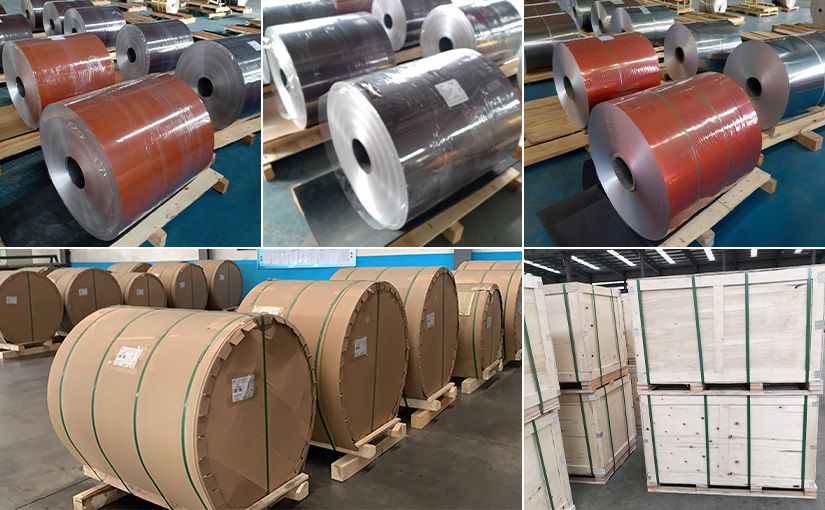

The surface of our aluminium foil has no stains, no marks, no fissure, no hole, no perforations, no lines without lacquers and breaks, exports to Germany, Poland, United Kingdom, Algeria, Brazil, etc.

Alloy | 8011, 8079 |

Temper | O, H22, H24 |

Thickness | 0.04mm - 0.15mm (commonly 0.05mm, 0.06mm, 0.07mm, 0.08mm, 0.1mm, 0.11mm, 0.12mm, 0.15mm) |

Width | 200mm - 1400mm (commonly 150mm, 914mm, or custom) |

Lacquered | One side or both sides |

Color | Terracotta, White, Black, Blue, Green (colors can be customized based on client requirements) |

Coating Thickness | ≤26μm (customized according to client needs) |

Inner Diameter | 76.2mm, 152mm |

Outer Diameter | <580mm |

Standards | ASTM B209, EN 546-2, EN 485-2, EN 573-3 |

PE color coated aluminum foil

Coating Thickness: 15-25 microns

PE Color Coated Aluminum Foil is coated with a layer of polyester (PE) on the surface of the aluminum foil, which is then baked at high temperatures to form a strong protective film. This coating has excellent flexibility and decorative properties, with a rich range of colors and high gloss.

PVDF color coated aluminum foil

Coating Types: Traditional PVDF Coating, Nano PVDF Coating

Two-Layer Thickness:25-28 microns

Three-Layer Thickness:35-45 microns

PVDF coating uses polyvinylidene fluoride (PVDF) resin as the primary component, which is baked at high temperatures to form a tough coating film. This coating offers exceptional weather resistance and UV resistance, ensuring it does not fade over extended periods of use.

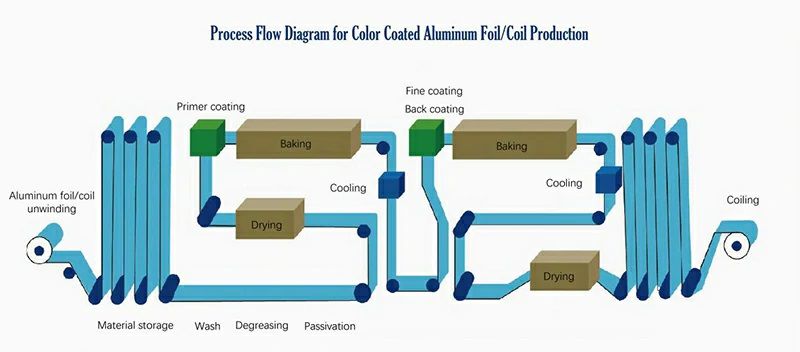

Uncoiling → pretreatment (the first pickling → the second pickling → the third pickling → → water washing → the first drying → passivation treatment → the second drying → roller coating → the second drying→winding.

Superior Waterproofing:

The composite material of asphalt and color coated aluminum foil provides excellent waterproofing, preventing moisture penetration around roofs and skylights.

Strong Weather Resistance:

The surface coating of color coated aluminum foil resists UV rays, acid rain, and harsh weather, maintaining stability and corrosion resistance over time.

Thermal Reflectivity:

The aluminum foil's excellent reflective properties help reduce heat absorption in the roof, lowering indoor temperatures and saving energy.

High Tensile Strength:

The material structure enhances tensile strength, resisting temperature fluctuations and external impacts to avoid cracking in the waterproof layer.

Easy Installation:

Flexible material that is easy to lay and cut, ideal for complex roof structures, reducing construction time and cost.

Long-lasting Insulation:

Prevents heat buildup on the roof, ensuring comfortable indoor temperatures, especially during summer, and reducing air conditioning usage.

Roof waterproofing projects

Color coated aluminum foil, combined with asphalt, creates waterproof membranes ideal for roof and skylight waterproofing. It offers excellent waterproofing and superior weather resistance, making it essential for skylight projects.

Roof Waterproofing: Color coated aluminum foil can be laminated with asphalt materials to create waterproof membranes, suitable for new construction and roof repairs, especially for flat and pitched roofs.

Basement Waterproofing: In addition to roofing, color coated aluminum foil asphalt waterproof membranes are also used in underground structures like basements and subways, ensuring moisture and waterproofing protection.

Skylight Waterproofing: Combining color coated aluminum foil with waterproof membranes enhances water resistance and UV protection, offering additional waterproofing for skylights.

Bridges and Tunnels: In special projects, color coated aluminum foil asphalt waterproof membranes are also used in bridges, tunnels, and other structures, particularly in high-moisture and high-water-pressure environments.

Roof insulation system

Roofs are key areas for heat loss and gain. color-coated aluminum foil improves insulation with excellent thermal resistance, making it ideal for roof insulation and thermal barrier applications.

1) LCL by wooden box package, fumigation wooden box is available

2) FCL by wooden box package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)