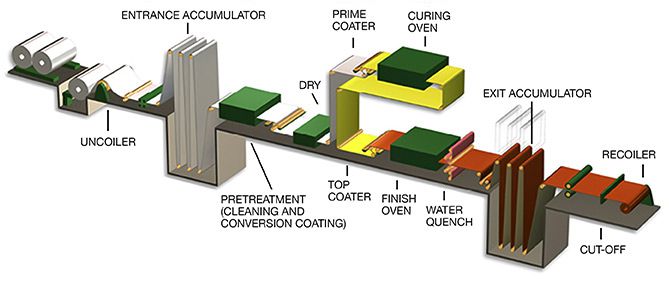

Color coated aluminum sheets are specially coated aluminum products with various excellent properties and wide applications. They are made from color coated aluminum coils through longitudinal slitting or transverse cutting, meeting the needs of different clients and industries.

Colour coated aluminium sheets are a versatile and practical solution for a wide range of applications, combining aesthetic appeal with durability and performance. Whether for architectural projects, signage, or industrial uses, they offer a reliable option for those looking for lightweight and attractive materials.

Alloy | 1050, 1060, 1070, 1100, 3003, 5052, 5052, 5005, 5006, 5052, 5754, 5182 |

Thickness | 0.2-1.5mm |

Width | 10-1800mm |

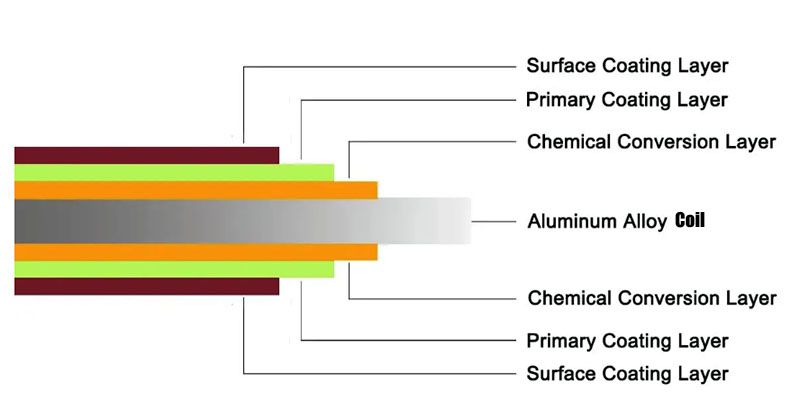

Coating Surface | PVDF/ PE/HDP/FEVE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, Sheet, Strips, Plate, Foil |

Applications | Roofing System and Ceiling Decoration |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

PE(Polyester) Coating:

A common choice for outdoor applications due to its durability and resistance to fading.

PVDF (Polyvinylidene Fluoride) Coating:

Offers superior weathering, UV resistance and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years

FEVE: Three coats: 15-20 years.

Technical Data:

Coating | POLYESTER | PVDF |

Item | Technical requirements | Technical requirements |

Thickness of coating film | ≥ 18 µm | ≥ 25µm |

Gloss deviation | gloss<70, tolerance≤10% | gloss<70, tolerance≤10% |

gloss≥70, tolerance≤5% | gloss≥70, tolerance≤5% | |

Hardness of pencil | ≥3H | ≥3H |

Adhesion | no lower than class 1 | no lower than class 1 |

Flexibility | ≤2T | ≤2T |

Boiling water resistance | no change (2h) | no change (2h) |

Color difference | ΔE≤2.0 | ΔE≤2.0 |

MEK | ≥100 times | ≥150 times |

Standard Colors

The standard color of color coated aluminum sheet is modulated according to the RAL color card. The basic colors are red, yellow, blue, green, white, gray and other colors and their derivative colors, which are suitable for most conventional applications.

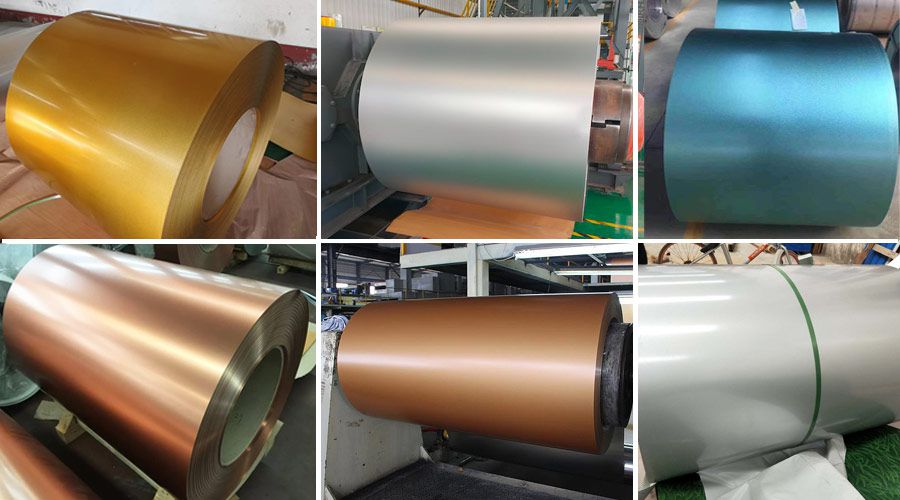

Metallic Colors

The Metallic color of color coated aluminum sheet simulate metal textures, such as silver gray, bronze, rose gold, etc., which add a sense of luxury and class to the product and are often used in high-end architectural decoration.

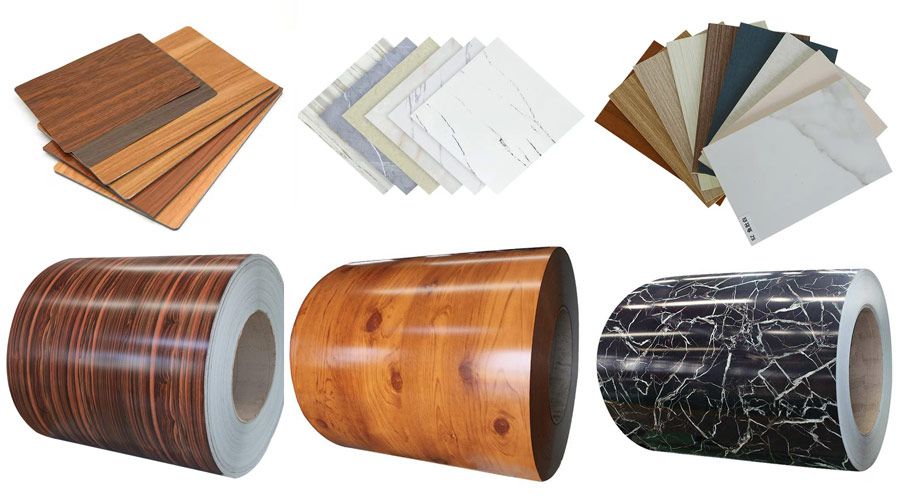

Printing Series

The printing series achieve natural texture effects such as wood grain and stone grain through special coating technology, providing more diversified choices for architectural design, esuitable for places that pursue natural and environmental protection concepts.

More details at: Aluminum Coil Coating

Model | 1000 Series Color Coated Aluminum Sheet | 3000 Series Color Coated Aluminum Sheet | 5000 Series Color Coated Aluminum Sheet |

Main Composition | High-Purity Aluminum (≥99%) | Al-Mn Alloy | Al-Mg Alloy |

Strength | Relatively Low, Easy To Form | Medium Strength, Better Impact Resistance | High Strength, Excellent Tensile Properties |

Corrosion Resistance | Good, Suitable For General Environments | Better, Suitable For Outdoor And Humid Conditions | Excellent, Ideal For Marine And High Salt-Spray Environments |

Workability | Easy To Process, Great Ductility | Good Workability | Good Workability |

Cost | Low-Economical Option | Medium-Good Cost-Performance Ratio | Higher-For Premium Applications |

Typical Applications | Building Decoration, Packaging, Interior Use | Roofing Sheets, Wall Panels, Insulation Boards | Shipbuilding, Marine Projects, Transportation, Industrial Structures |

Surface Finish & Coating Compatibility | • Good Surface Smoothness | • Better Coating Adhesion | • Excellent Surface Stability |

Weather / UV Resistance | • Suitable For Indoor Use | • Suitable For Long-Term Outdoor Use | • Excellent For Extreme Climates |

Service Life | • Short To Medium Term | • Medium To Long Term | • Long-Lasting Durability |

Durability:

The color coated finish is often more durable than post-painted surfaces, as it is baked on and adheres well to the aluminum, providing resistance to scratches, corrosion, and UV degradation.

Aesthetic Variety:

Color coated aluminum sheet comes in a wide range of colors and finishes, including matte, gloss, and textured surfaces, allowing for greater design flexibility.

Cost-Effectiveness:

Color coating reduces the need for additional painting processes after fabrication, which can save time and labor costs.

Environmental Considerations:

Many colour coated aluminum sheet products utilize eco-friendly coatings and processes, which can lead to lower VOC emissions compared to traditional painting methods.

Maintenance:

Color coated surfaces are generally easier to clean and maintain compared to uncoated or post-painted surfaces.|

Architectural Facades:

Many modern buildings incorporate color coated aluminum sheet for decorative and functional facade cladding due to their durability and design flexibility.

Interior Design Elements:

From ceiling tiles to wall panels, the attractive finishes complement many interior styles, offering aesthetic advantages.

Transportation:

In elements of road vehicles, from bodywork to trailers, the lightweight characteristics contribute to fuel efficiency without sacrificing structural integrity.

Consumer Products:

Items like signboards, appliances, and furniture often utilize color coated aluminum for its combination of form, function, and finish.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)