Red aluminum sheet have been coated with a red finish, typically using a process like powder coating or a paint application. This coating not only provides the desired color but also enhances the durability and aesthetic appeal of the aluminum.

Red color coated aluminum sheets offer a rich palette of hues, customizable according to RAL and Pantone color charts. They can also be matched to customer samples to meet diverse design requirements, such as high-gloss scarlet or tangerine red. These vibrant colors infuse spaces with a dynamic and passionate visual impact.

Alloy | 1050, 1060, 1070, 1100, 3003, 3004, 3105, 5005, 5052, 5754, 5182, 6061, 8011 |

Thickness | 0.2-1.5mm |

Width | 30-1800mm |

Coating Surface | PVDF/ PE/HDPE/FEVE/EOXY/ PU |

Coating Thickness | Single Coating (4-20 Um) |

Double Coating (25-28 Um) | |

Triple Coating (35-38 Um) | |

Temper | O,H12,H22,H14,H24,H16,H26,H18,H26,etc. |

Color | All Ral Color or As Request |

Type | Coil, sheet, strips, plate |

Applications | Building, Decoration, Transportation, Signage, Electronics, Etc |

MOQ | 2 tons per size |

Standards and Specifications

ASTM | B209 |

ISO | ISO 26204 (alloy designations), ISO 6892 (mechanical testing),ISO 9001,ISO 14001. |

UNS | A91050 (United States Numbering System) |

Red coated aluminum sheets are available in various RAL codes.

RAL 3000 - Flame Red

RAL 3001 - Signal Red

RAL 3002 - Red Orange

RAL 3003 - Ruby Red

RAL 3020 - Traffic Red

PE(Polyester) Coating:

A common choice for outdoor applications due to its durability and resistance to fading.

PVDF (Polyvinylidene Fluoride) Coating:

Offers superior weathering, UV resistance and a long lifespan, often used for architectural applications.

Warrantly:

Regular PE: 3-5 years;

High Performance PE: 6-9 years;

PVDF: 15 years;

FEVE: Two coats: between 10-15 years

FEVE: Three coats: 15-20 years.

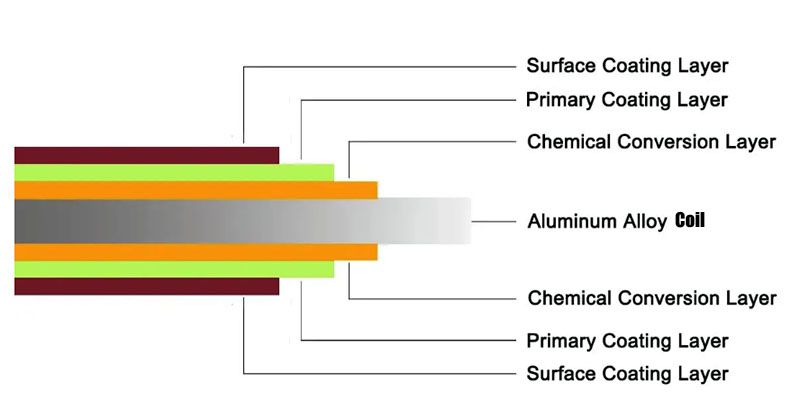

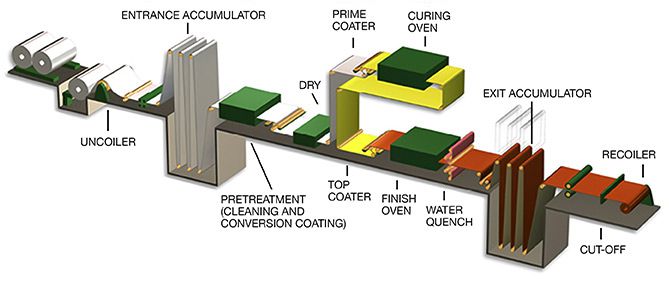

1. Surface Preparation:

The aluminum sheet is cleaned and treated to ensure proper adhesion of the coating material.

2. Primer Application:

A primer layer is applied to enhance adhesion between the aluminum substrate and the topcoat.

3. Color Coating:

The desired color or resin is applied to the primed aluminum sheet using techniques such as roller coating, spray coating, or coil coating.

4. Curing:

The Red coated aluminum sheet is then cured at high temperatures to ensure proper bonding and curing of the coating layers.

Durability:

The coating provides additional protection against corrosion, UV rays, and environmental factors, extending the lifespan of the aluminum.

Aesthetic Appeal:

The vibrant red finish can enhance the visual appeal of products and structures.

Low Maintenance:

Coated aluminum surfaces are generally easy to clean and maintain.

Lightweight:

Aluminum is inherently lightweight, making it easier to handle and install.

Versatility:

Red coated aluminum sheets can be used in various applications, from architectural elements to signage.

Architectural Cladding:

For buildings and facades, providing both aesthetic appeal and protection.

Signage:

Used for outdoor and indoor signs due to their visibility and weather resistance.

Automotive Parts:

For decorative elements and components that require lightweight materials with good corrosion resistance.

Industrial Applications:

In equipment and machinery where color coding is necessary or for safety warnings.

Furniture:

For modern design pieces that require a durable yet stylish finish.

1) LCL by wooden pallet package, fumigation wooden pallet is available

2) FCL by wooden pallet package loaded in the container

3) FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity)