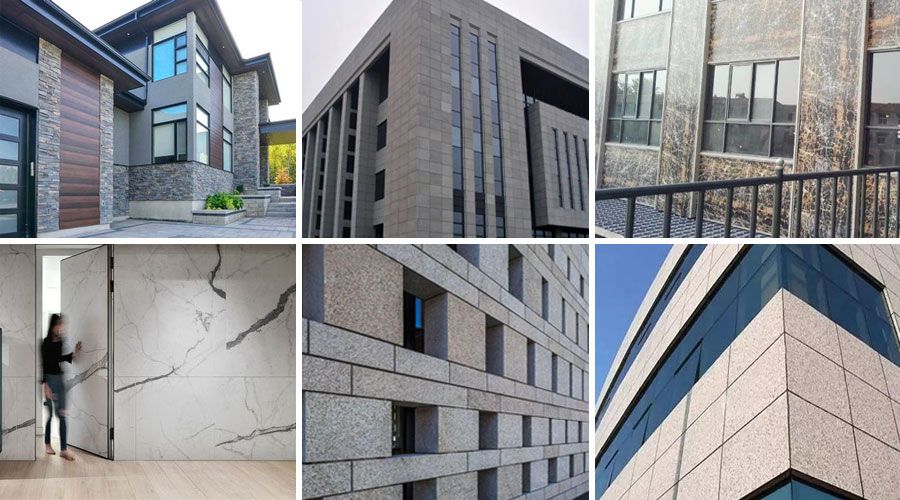

Granite color coated aluminum coil features a granite-like texture or color. Combining the lightweight and corrosion-resistant properties of aluminum coil with the decorative effects of granite, it is widely used in architectural curtain walls, interior and exterior decoration and other applications.

The substrate of granite aluminum coil utilize 1000 series (e.g., 1060), 3000 series (e.g., 3003, 3004, 3104, 3105), or 5000 series (e.g., 5052) aluminum alloys. These aluminum coils offer advantages such as lightweight (density approximately 2.7g/cm³), high strength, and corrosion resistance. Surface coatings are primarily categorized into two types:

- Polyester (PE) coatings:

These are lower-cost and suitable for indoor and outdoor environments. They have a dry film thickness of ≥16μm, a warranty of approximately 10 years, a pencil hardness of ≥HB, and exhibit no significant corrosion after a 720-hour salt spray test.

- Fluorocarbon (PVDF) coating: Offers superior performance and strong weather resistance (ΔE ≤ 4.0 after 4000 hours of UV exposure). Suitable for high-rise building exteriors or coastal areas. Dry film thickness ≥ 25μm, warranty period ≥ 15 years, pencil hardness ≥ 2H, impact strength ≥ 50kg/cm.

Texture simulation technology of granite coated aluminum coil uses high-resolution scanning of real granite textures, combined with roller printing or powder spraying, to achieve a highly realistic reproduction of the stone's texture. Some high-end products utilize a three-coat process (primer + basecoat + clearcoat), achieving a film thickness tolerance within 0.5μm, resulting in a strong three-dimensional texture and high color uniformity.

Performance Parameters

Mechanical Properties: T-bend test ≤ 2T, adhesion reaches Grade 0 (ASTM D3359), and no cracking or peeling when bent.

Environmental Indicators: Complies with national standards ISO 14001 environmental management system certification. The coating is recyclable.

Production Process of Granite Stone Grain Aluminum Sheet:

- Substrate Pretreatment

The aluminum coil is cleaned and passivated to remove surface impurities and create a microstructure that facilitates coating adhesion.

- Coating

Using processes such as roller coating and spraying, the prepared coating is evenly applied to the aluminum coil surface, creating a granite-like texture or color.

- Bake-Curing

High-temperature baking allows the coating to bond tightly to the aluminum substrate, improving adhesion and weather resistance.

- Post-Processing

Embossing and lamination can be performed as needed to enhance the product's decorative effect and functionality.

Features of Granite Color Coated Aluminum Coil:

- High Decorative Properties

Using processes such as roller coating and spraying, the aluminum coil surface is treated with a granite-like texture or color, providing a realistic stone texture to meet personalized architectural needs.

- Lightweight and High Strength

The aluminum coil substrate has a low density, weighing only 1/3 to 1/5 of traditional stone, making it easy to transport and install while maintaining high bending and flexural strength.

- Excellent Weather Resistance

The coating utilizes high-performance materials such as fluorocarbon paint and polyester paint, offering excellent resistance to UV rays, acid rain, and salt spray. It resists fading and chalking over time, with a lifespan of 15-20 years.

- Excellent Processability

It can be bent, cut, and punched into a variety of shapes to accommodate complex architectural designs, such as curved curtain walls and custom-shaped decorative pieces.

- Environmentally Friendly and Energy-Saving

Aluminum coils are recyclable, aligning with the concept of a circular economy. The coating production process produces low volatile matter, meeting environmental standards.

Applications of Granite Coated Aluminum Coil:

- Architectural Curtain Walls

As an alternative to traditional stone for exterior walls of high-rise buildings and commercial complexes, it reduces structural loads while enhancing the aesthetics of the building.

- Interior Decoration

Used for wall and ceiling decoration in public spaces such as shopping malls, hotels, and airports, creating a high-end, natural atmosphere.

- Billboards and Signs

The lightweight and durable properties make it an ideal material for outdoor billboards and signage systems.

- Home Appliances and Electronics

Granite color coated aluminum coils are used in some home appliance housings and electronic device panels to enhance the product's quality.

Granite color coated aluminum coil has become an important material in the field of architectural decoration due to its high cost-effectiveness, easy processing and environmental protection characteristics.