In building envelope engineering, the selection of spandrel materials directly affects structural safety, service life, and overall economic benefits. As a Canadian manufacturer specializing in the research and development of color coated aluminum coils, we BCM Alu have been deeply involved in the industry for many years and understand the stringent requirements for weather resistance, mechanical properties, and compatibility of materials used in wall and ceiling spandrel panels applications.

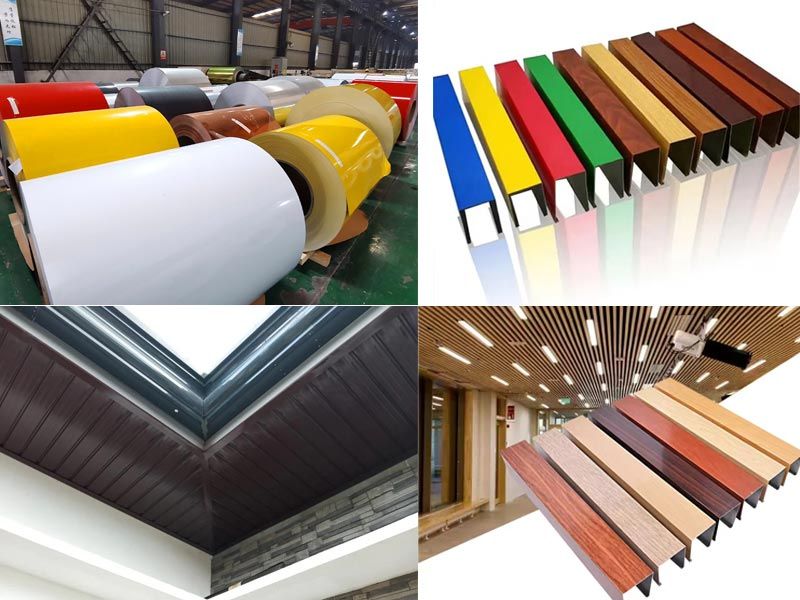

From a basic product perspective, our color coated aluminum coil for spandrel panels use 3003 and 3004 series aluminum substrates. These two series of aluminum materials, containing manganese, possess superior tensile strength and fatigue resistance compared to pure aluminum. The substrate thickness ranges from 0.3mm to 1.2mm, and the width can be customized to standard specifications such as 1000mm, 1220mm, and 1500mm according to project requirements. The coil inner diameter is uniformly 508mm, and the weight of a single coil is controlled between 2.5 and 5 tons, making it suitable for the processing needs of various continuous roll forming equipment.

The coating system employs two mainstream solutions: industry-leading PVDF fluorocarbon coating and PE polyester coating. The PVDF coating uses a formula with over 70% fluorocarbon resin content, formed through a two-coat, two-bake process, with a dry film thickness controlled at 25-35μm. The PE polyester coating has a dry film thickness of 20-30μm, meeting the needs of different climatic environments and service life.

In terms of color, in addition to the full range of colors from the standard RAL color chart, special colors such as metallic and matte can be customized according to project requirements. The coating adhesion meets GB/T 9286-1998 standard Grade 1, and the pencil hardness is ≥2H, ensuring the integrity of the coating during processing and use.

Combined with the application scenarios of spandrel panels, the core advantage of our color coated aluminum coils lies primarily in their exceptional weather resistance. The high latitude, strong ultraviolet radiation, and large temperature differences of the Canadian climate necessitate weather resistance as a core indicator during the product development stage. According to third-party testing, PVDF coated products exhibit a color difference ΔE ≤ 1.5 and gloss retention ≥ 85% after 1000 hours of xenon lamp aging in accelerated aging tests. They can withstand extreme temperature variations from -40℃ to 70℃. In harsh environments such as high-salt-spray conditions at the seaside and industrial pollution, they show no rust after over 1000 hours of salt spray testing. This performance allows for a service life of over 25 years in various outdoor building wall and beam applications, far superior to traditional coating materials.

The balance between lightweight and mechanical adaptability is a key advantage for its suitability for spandrel applications. The aluminum coil substrate has a density of only 2.7g/cm³, reducing weight by more than 60% compared to steel. This significantly reduces the load on the building structure, making it particularly suitable for spandrel systems in large-span, high-rise buildings. Meanwhile, by precisely controlling the substrate rolling process and coating curing parameters, the color coated aluminum coil product achieves a tensile strength of 110-150 MPa and a yield strength ≥75 MPa. The roll-formed wall beams and panels effectively resist external forces such as wind and seismic loads. In actual engineering projects in windy regions such as Quebec and Ontario, Canada, its wind pressure resistance meets or exceeds C5 level in the GB/T 50009-2012 standard, ensuring the structural stability of the enclosure system.

Furthermore, excellent processing adaptability and environmental friendliness are also noteworthy. BCM Alu’s color coated aluminum coils have a surface flatness error ≤0.2 mm/m, and the coating surface roughness Ra is controlled within 0.8-1.2 μm, allowing for smooth processing of various techniques such as bending, stamping, and roll forming. The formed spandrel panels have tight joints and a smooth appearance, requiring no additional secondary treatment. From an environmental perspective, aluminum substrates are 100% recyclable, with recycling energy consumption only 5% of that of virgin production, aligning with global green building trends. Their long service life and low maintenance significantly reduce the overall lifecycle maintenance costs of projects; calculations show that compared to traditional color-coated steel wall panels, the total lifecycle cost can be reduced by more than 30%.

The core value of color coated aluminum coils for spandrel panels lies in achieving safe, long-lasting, economical, and environmentally friendly building envelope solutions through precise matching of material properties with application scenarios. Leveraging our R&D and production experience in Canada's harsh climate, we provide more adaptable products for various building projects worldwide through precise parameter control and stable quality assurance.